In the realm of metallurgy, where strength and resilience are paramount, the term “alloy steel” often emerges as a beacon of potential. The world of materials science is a captivating journey through which we seek to understand the intricacies that grant certain alloys their remarkable strength. From towering skyscrapers to high-performance machinery, alloy steel’s prowess shapes the very fabric of our modern infrastructure. But how strong is alloy steel exactly? What lies beneath its surface that bestows it with this coveted attribute? In this exploration, we embark on a scientific quest to unveil the secrets of alloy steel’s strength, unraveling the alchemical symphony that melds elements into formidable structures. Join us as we dive into the depths of alloy steel’s composition, properties, and applications, and uncover the truth behind its undeniable strength.

is alloy steel strong?

Yes, alloy steel is indeed strong. Alloy steel is a type of steel that has been enhanced with various alloying elements such as chromium, nickel, molybdenum, and manganese, among others. These alloying elements are strategically added by alloy steel manufacturers in specific proportions to alter the microstructure of the steel, resulting in improved mechanical properties, including increased strength of alloy steel.

Strength, the capacity of a material to withstand forces without yielding, is a fundamental property that underpins the functionality and reliability of countless structures and components. From towering skyscrapers to intricate machinery, strength is the cornerstone of design and innovation. In this blog, we embark on a journey to delve into the realm of material strength, with a specific focus on the exceptional strength of alloy steel.

What is alloy steel?

Alloy steel, a remarkable fusion of metallurgy and engineering, is a specialized type of steel that goes beyond the conventional properties of carbon steel. It is meticulously crafted by introducing specific alloying elements into the steel matrix, transforming its characteristics to achieve enhanced properties.

Alloy steel’s composition varies based on its intended application, and alloy steel manufacturers play a pivotal role in tailoring these compositions to meet precise requirements. Common alloying elements include chromium, nickel, manganese, molybdenum, and vanadium, among others. These elements are introduced in varying proportions to create alloys with specific attributes such as increased strength, improved corrosion resistance, and enhanced heat resistance.

Purpose of Alloying Elements in Enhancing Steel's Properties

Alloying elements play a pivotal role in enhancing the properties of steel, transforming it into alloy steel with tailored characteristics that surpass those of plain carbon steel. Each alloying element serves a specific purpose, contributing to the overall improvement of the material’s mechanical, thermal, and corrosion resistance properties.

Resistance

Alloying elements, such as chromium and molybdenum, form solid solutions with iron, which alter the crystal structure and strengthen the material. These interactions obstruct dislocation movement within the crystal lattice, making it more difficult for the material to deform under stress. This results in higher tensile strength and hardness.

Resistance

Elements like chromium and nickel form protective oxide layers on the surface of the steel, enhancing its resistance to corrosion and oxidation. This makes alloy steel suitable for applications exposed to harsh environments or chemicals.

Some alloying elements promote the formation of fine-grained structures, enhancing toughness and ductility. This is crucial in applications where the material must withstand impacts or sudden loads.

Elements like vanadium and tungsten contribute to improved heat resistance and stability at elevated temperatures, making alloy steel suitable for high-temperature applications such as turbine blades.

Alloying elements can enhance the material’s ability to resist wear and abrasion, making alloy steel suitable for applications involving friction and contact.

Alloying elements are meticulously chosen based on the desired properties for a specific application. Alloy steel manufacturers combine their expertise with scientific insights to formulate the precise alloy composition that achieves the optimal balance of strength, durability, and other essential attributes. This intricate interplay of elements and engineering contributes to the exceptional strength of alloy steel.

How Microstructure Shapes Strength of alloy steel?

The microstructure of alloy steel is like a hidden world within the material, where atoms arrange themselves in unique patterns. This arrangement can take different forms, such as fine-grained structures or tiny particles of alloying elements spread throughout the material.

When the microstructure consists of fine-grained structures, it means that the atoms are closely packed together in small groups. This gives the steel added toughness and the ability to absorb impacts without easily breaking. On the other hand, when there are dispersed particles of alloying elements within the material, it’s like having reinforcements scattered throughout. This creates a strong network that makes the steel more resistant to wear and provides an extra boost to its overall strength.

Think of it like a puzzle where the pieces fit together in specific ways. Each type of microstructure puzzle piece influences how the steel responds when forces are applied to it. Alloy steel manufacturers have the skill to design these puzzle pieces, adjusting the microstructure to suit the intended use of the alloy steel. This precise control over the microstructure is what makes alloy steel so strong and versatile in various applications.

Strength Comparison:

Alloy Steel vs. Carbon Steel

In the realm of material strength, alloy steel and carbon steel stand as prominent contenders. Alloy steel, bolstered by alloying elements, exhibits markedly enhanced strength compared to carbon steel. The infusion of elements like chromium and nickel refines its microstructure, imparting greater tensile strength and hardness. In contrast, carbon steel’s strength primarily arises from its carbon content, rendering it relatively less robust than alloy steel.

Alloy steel harnesses the power of alloying elements, which act as agents of transformation within its microstructure. Chromium, for instance, forms a protective layer that shields the steel from corrosion and oxidation. This layer not only enhances longevity but also bolsters the structural integrity, contributing to its strength. Nickel, another common alloying element, introduces temperature stability, making alloy steel resilient even in extreme conditions. The combination of these elements creates a harmonious synergy, amplifying the material’s overall strength.

The microstructure of alloy steel is engineered to perfection through precise control of alloying ratios and heat treatment processes. This tailored approach creates a material with finely dispersed alloying element precipitates, resembling fortified bulwarks within the steel matrix. These microstructural reinforcements significantly impede dislocation movement and grain boundary motion, contributing to higher strength levels.

In contrast, carbon steel’s strength relies primarily on its carbon content. While carbon steel offers reasonable strength, it pales in comparison to alloy steel’s targeted enhancement. Carbon steel’s microstructure lacks the fine-tuned arrangement of alloying element-induced precipitates found in alloy steel. This disparity in microstructural reinforcement directly translates to a marked difference in strength.

In essence, the inherent superiority of alloy steel in strength is a result of meticulous engineering involving the orchestration of alloying elements and microstructure refinement. This distinct advantage over carbon steel underscores alloy steel’s pivotal role in applications demanding exceptional strength, making it the preferred choice for industries requiring materials capable of withstanding rigorous stresses and dynamic forces.

Alloy Steel's Versatility Across Industries

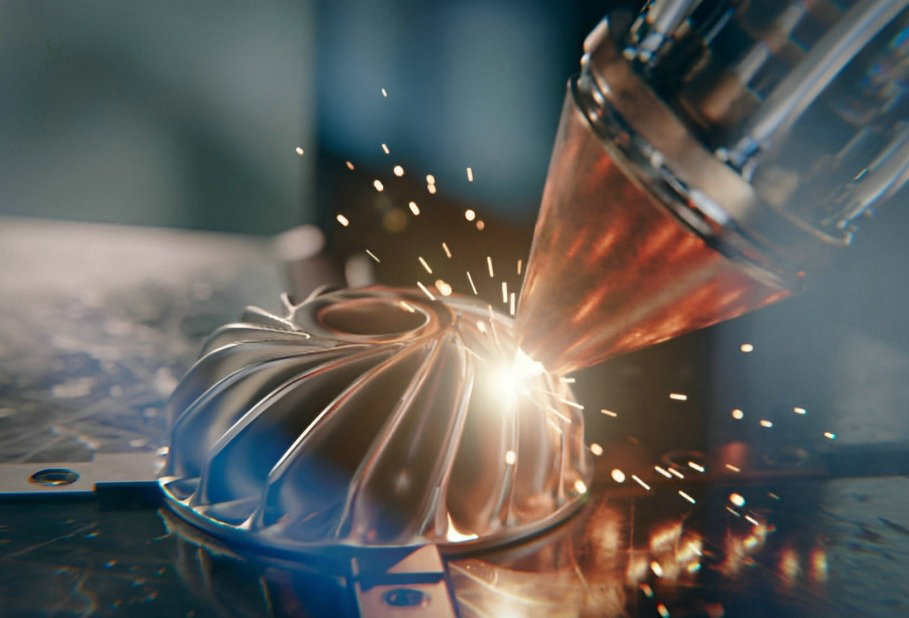

The exceptional strength of alloy steel, a product of meticulous engineering, finds its application across diverse industrial sectors, showcasing its unrivaled capabilities.

-

Automotive Precision

In the automotive realm, alloy steel reigns supreme in critical components like engine parts, drive shafts, and suspension components. Its formidable strength ensures optimal performance, even under high-speed and high-stress conditions. The advanced microstructure and alloying element integration make alloy steel an indispensable choice for achieving safety, reliability, and efficiency on the road. -

Construction Excellence

Alloy steel stands tall in the construction industry, reinforcing structural elements in skyscrapers, bridges, and mega-infrastructure projects. Its strength ensures load-bearing capacity and resilience against external forces. The synergy of alloying elements fortifies alloy steel against corrosion, extending its service life even in demanding environments. -

Aerospace Precision

Aerospace engineering embraces alloy steel's strength for aircraft landing gear, engine components, and structural elements. Its robustness ensures safety during takeoffs, landings, and high-altitude flights. The ability to endure extreme temperatures and stressors aligns alloy steel with aerospace's stringent requirements. -

Critical Components Demanding Strength

Within these industries, alloy steel fortifies components that bear substantial loads and experience dynamic forces. Crankshafts in engines, beams in skyscrapers, and landing gear in aircraft all rely on alloy steel's strength to ensure structural integrity and operational success. Alloy steel's microstructural finesse and alloying element influence provide the backbone of reliability in such critical applications.

In essence, the strength of alloy steel serves as the common denominator in its versatile applications. Alloy steel manufacturers precision ensures that alloy steel is uniquely tailored to address specific industrial needs, underpinning its indispensability across automotive, construction, aerospace, and beyond.

Future Directions and Innovations

The trajectory of alloy steel’s future is marked by continuous scientific exploration, driven by the quest for even greater strength and performance.

Advancing strength of Alloy Steel

-

Nanotechnology Insights

Ongoing research delves into the realm of nanotechnology, aiming to engineer alloy steel at the atomic and molecular scales. By manipulating materials at this level, alloy steel manufacturers seek to fine-tune microstructural arrangements for unparalleled strength. These advances not only redefine the boundaries of alloy steel strength but also offer avenues to enhance other properties, such as thermal conductivity and wear resistance. -

Computational Modeling Precision

Modern computational tools enable in-depth simulations of alloy steel's behavior under varying conditions. Researchers collaborate with alloy steel manufacturers to optimize alloying element ratios, predict microstructural outcomes, and tailor alloy steel for specific applications. This approach accelerates the development of alloy steel with precisely tailored strength profiles, addressing industry needs more effectively.

Emerging Technologies in Alloy Steel Production

Innovations in alloy steel production methodologies hold the key to unlocking novel avenues for strength enhancement.

-

Additive Manufacturing Marvels

Additive manufacturing, or 3D printing, introduces a paradigm shift in alloy steel production. By precisely layering materials, researchers and alloy steel manufacturers can control microstructural evolution with unprecedented precision. This technology not only accelerates the development cycle but also allows for the creation of intricate geometries with enhanced strength, catering to industries seeking lightweight, robust components. -

Eco-Friendly Alloys

As sustainability gains prominence, alloy steel manufacturers delve into developing eco-friendly alloys. These alloys seek to maintain or even enhance the strength of traditional alloy steel while minimizing the environmental impact of production processes. This innovation aligns alloy steel's strength with a greener future, where industries aim to reduce their carbon footprint.

In summary, alloy steel’s future trajectory lies in the convergence of nanotechnology insights, computational precision, additive manufacturing, and eco-friendly initiatives. The pursuit of greater strength, driven by ongoing research and emerging production methodologies, cements alloy steel’s status as an evolving and indispensable material in industries seeking enhanced performance and durability.

Conclusion

In this exploration of alloy steel’s strength, we’ve delved into its microstructural intricacies, alloying element synergies, and its application across diverse industries. We’ve uncovered the precise calibration of alloying ratios and manufacturing techniques by alloy steel manufacturers, resulting in a material endowed with unparalleled strength and performance attributes.

Remarkable strength of alloy steel reverberates through modern engineering and industries, underpinning structures, machines, and components crucial to our daily lives. Alloy steel manufacturers expertise in designing and fine-tuning its microstructure empowers alloy steel to excel in demanding applications, from skyscrapers to aerospace machinery. The alloy steel’s strength isn’t just a property; it’s a catalyst for innovation, enabling advancements across sectors.

In a world marked by evolving challenges and ambitious endeavors, alloy steel’s strength stands as a testament to human ingenuity and scientific mastery. Its unwavering presence, driven by the expertise of alloy steel manufacturers and advancements in materials science, solidifies its place as an essential cornerstone material in the fabric of modern civilization. As technology advances and industries evolve, the enduring strength of alloy steel continues to shape the course of progress, ushering in a future where strength and performance know no bounds.