Professional copper alloy brass manufacturers

Brass: Blending Brilliance with Resilience!

Your Trusted brass manufacturers for One-Stop metal solution provider

Based in Shanghai, China, Alloyours stands as a premier alloy supplier specializing in brass alloys.

Through the seamless integration of advanced technologies and traditional craftsmanship, we excel in producing a comprehensive range of brass, copper, and forged bronze alloys. Our product line includes an extensive array of bars, rods, tubes, rectangles, wires, hollow rods, and profiles, tailored to meet the diverse demands of our global clientele.

Request a quote today and experience our commitment to delivering superior quality and tailored services that transcend borders.

Customized solutions

We focus on providing customized brass alloys for our customers to ensure that their specific specifications and requirements are met to cope with various complex application scenarios.

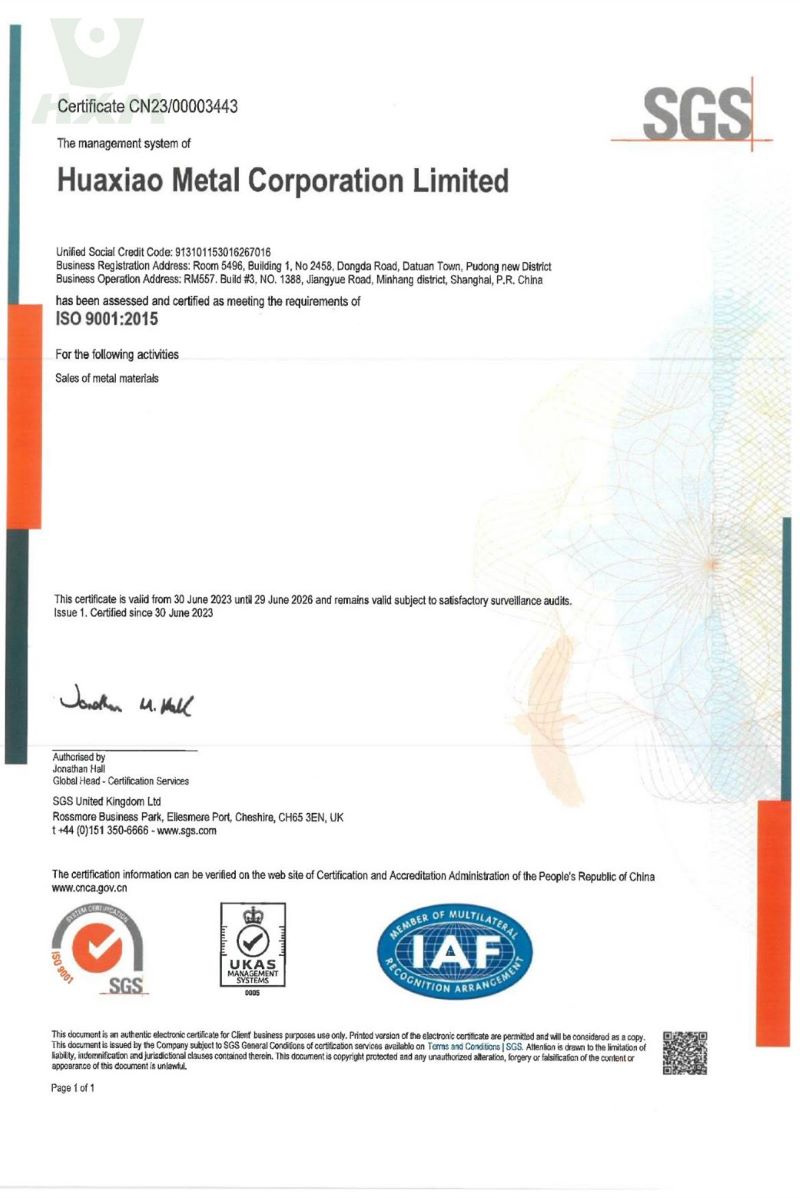

Quality Assurance

We strictly control the production process to ensure that each batch of products meets the highest quality standards and ensures consistent performance and reliability.

Global service

As an international company, we have a global service coverage and are able to respond to customer needs in a timely manner and provide full support and assistance.

Applications

Versatile Solutions for Diverse Applications

Brass alloys stand as a hallmark of versatility and reliability across an extensive spectrum of industries. Renowned for their exceptional mechanical properties, corrosion resistance, and aesthetic appeal, brass alloys find widespread application in various sectors, showcasing their adaptability and performance in demanding environments.

- Manufacturing

- Architecture

- Electrical

- Marine

- Musical Instruments

- Artistry

Testimonials

What They Said

At Alloyours, we pride ourselves on being able to fulfill the needs of our customers in a variety of industries and have received positive reviews from our customers around the globe. These are just a few of the things our customers really feel about our products and services:

Using Alloyours brass rods for our trumpet, the material is quite durable and makes our instruments perform even better. They have a good service and we will call them again in the future.

FAQs

Brass is classified based on various factors including its chemical composition, intended usage, and specific performance characteristics.

Chemical Composition-Based Classification:

- Alpha Brass: Contains a higher proportion of copper, typically exceeding 65%, with a lower content of zinc. These brass alloys exhibit excellent cold-working properties and are often used in manufacturing thin-walled tubes and cold-stamped components.

- Alpha-Beta Brass: Contains a moderate ratio of copper to zinc, ranging between 35% to 45%. These alloys possess good machining properties and mechanical strength, commonly utilized for producing nuts, bolts, and mechanical parts.

- Beta Brass: Comprises a higher percentage of zinc, usually exceeding 45%. Beta brass demonstrates good casting properties and corrosion resistance, commonly used in casting processes for various parts and decorative items.

Usage and Performance-Based Classification:

- Free-Cutting Brass: Includes additives to enhance machinability, suitable for manufacturing threaded components like screws and bolts.

- Muntz Metal: Consists of approximately 60% copper and 40% zinc, offering good resilience and corrosion resistance, often used in shipbuilding for rivets and bolts.

Specific Alloy-Based Classification:

- Lead-Free Brass: Excludes lead content, used for specific applications conforming to environmental and food safety standards.

- Dezincification-Resistant Brass: Contains specific alloying elements to improve corrosion resistance, frequently applied in the manufacturing of durable pipes and valves.

Brass manufacturers provide customized alloys based on these classifications to meet diverse client needs and specific applications.

In the manufacturing process of brass alloys by Alloyours brass manufacturers, copper and zinc serve as the primary elements. Copper, a ductile and malleable metal, constitutes the fundamental base of brass alloys, providing them with inherent conductivity and corrosion resistance. Zinc, an essential alloying element, is added to copper to form different compositions of brass alloys. The varying ratios of copper and zinc determine the specific properties and characteristics of the resulting brass alloy.

The manufacturing process typically involves melting the copper and zinc together at high temperatures, followed by controlled cooling to achieve the desired structure and properties. Often, other elements or additives might be incorporated to modify certain attributes of the brass alloy, such as lead to enhance machinability or other elements to improve dezincification resistance.

Brass alloys, manufactured by Alloyours brass manufacturers, find extensive applications across diverse industries due to their unique properties. Some prominent products crafted from brass alloys include:

Musical Instruments: Brass alloys are widely used in crafting musical instruments such as trumpets, saxophones, trombones, and French horns due to their superior acoustic properties, allowing for rich and resonant tones.

Architectural Hardware: Door handles, knobs, hinges, and decorative fixtures made from brass alloys not only offer durability but also impart an aesthetic appeal to architectural designs, making them popular in the construction industry.

Plumbing and Fittings: Brass alloys, with their corrosion-resistant properties, are favored for manufacturing valves, couplings, pipe fittings, and connectors in plumbing systems, ensuring reliability and longevity in various water-based applications.

Electrical Components: Brass alloys' exceptional electrical conductivity makes them suitable for producing electrical connectors, terminals, sockets, and switches in electrical systems, ensuring efficient transmission of electrical currents.

Automotive Parts: Various automotive components like radiator cores, gears, bushings, and decorative trims utilize brass alloys due to their wear resistance, durability, and ability to withstand high temperatures.

Precision Engineering: Brass alloys are employed in crafting precision components such as gears, bearings, fasteners, and intricate mechanical parts, benefiting from the material's machinability and strength.

Alloyours brass manufacturers employ cutting-edge techniques to precisely formulate brass alloys tailored to specific applications, ensuring optimal performance, durability, and reliability across these diverse product categories. Their expertise in alloy composition and manufacturing processes ensures the delivery of brass alloys that meet stringent quality standards demanded by various industries.

Alpha brass alloy, manufactured by Alloyours brass manufacturers, is a type of brass characterized by its higher copper content (typically above 65%) and lower zinc content. This composition results in a predominantly single-phase structure with a solid solution of zinc in copper. Alpha brass alloys exhibit excellent cold-working properties, high ductility, and good corrosion resistance. They are commonly utilized in applications requiring intricate cold-forming processes, such as thin-walled tubing, cold-stamped components, and some decorative applications.

Gamma brass is not a commonly recognized term in the classification of brass alloys. Brass alloys are primarily categorized as alpha, alpha-beta, and beta brass based on their copper-zinc ratios and microstructural properties. While alpha brass contains higher copper content and alpha-beta brass maintains a balanced composition, beta brass comprises a higher proportion of zinc. The term "gamma brass" is less commonly used in the categorization of brass alloys.

Contact information: Choose your usual contact information.

Email address:market004@alloyours.com

Phone number/WhatsApp:+86-13052085117

Request for Quotation: Send your request for quotation to Alloyours by e-mail or through the online contact form, specifying the type, specification and quantity of brass alloy you require.

Detailed Requirements: Provide details of your requirements such as specific alloy type, dimensions, quality standards and delivery time so that Alloyours can better understand your needs.

Discussion and negotiation: The Alloyours team will contact you to discuss the details and provide a quote. They may ask for further details to ensure the most suitable product is offered.

Contact Us

Location Name

RM557, NO.1388 Jiangyue Road, Shanghai China

Phone number/WhatsApp

+86-13052085117

email address

market004@alloyours.com