Alloy Products

OUR

Product

Alloyours is a leading alloy suppliers, specializing in providing high-quality alloys to industries worldwide.

Product

gallery

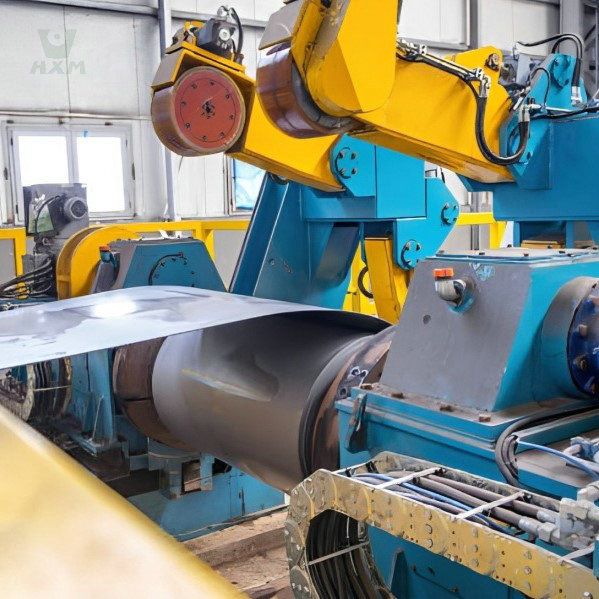

At Alloyours, our extensive product and multiple production lines enable us to deliver customized solutions to our valued customers.

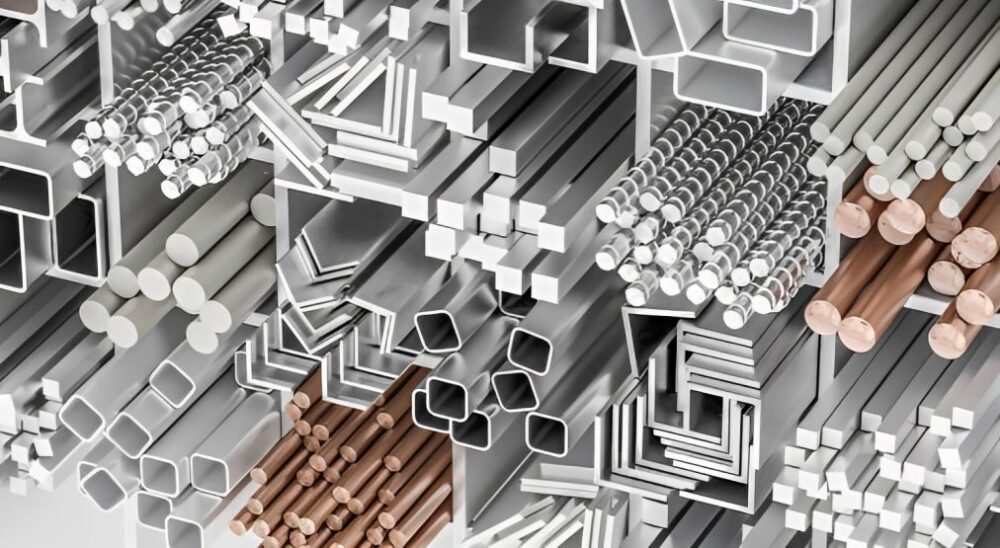

In terms of composition, our alloy suppliers encompass a variety of categories, including carbon steel alloys, stainless steel alloys, aluminum alloys, copper alloys, nickel alloys, and more. Each alloy composition offers unique properties and characteristics tailored to specific industry requirements.

Additionally, we classify our alloys based on their shape to provide versatile options. Our product range includes sheets, plates, bars, rods, tubes, wires, and custom-formed components.

With our diverse product classification and many production lines, we are committed to providing top-quality alloys that cater to the specific needs of different industries. We invite you to explore our extensive product range and discover the perfect alloy solution for your application.

OUR

Services

What is alloy?

An alloy is a substance that is made by combining two or more elements, with at least one of them being metal. When these elements are mixed together, they form a new material with properties that are different from those of the individual elements. Alloys are created to enhance specific characteristics such as strength, durability, corrosion resistance, and conductivity.

To understand alloys better, let’s consider an example: steel. Steel is one of the most widely used alloys. It is composed of iron as the base metal, with small amounts of carbon and other elements like chromium, nickel, and manganese added to it. The addition of these elements modifies the properties of iron, making steel stronger, more resistant to corrosion, and suitable for various applications, ranging from construction to manufacturing.

Alloys can have a wide range of compositions and structures, depending on the elements used and their proportions. Some alloys are created by melting and mixing the metals together, while others are formed through processes like powder metallurgy or solid-state diffusion. The choice of method depends on factors such as the desired properties, the metals involved, and the intended application of the alloy.

The applications of alloys are vast and diverse. They are used in industries such as aerospace, automotive, electronics, construction, and medicine. For example, aluminum alloys are used in aircraft construction due to their lightweight and high strength properties. Copper alloys are utilized in electrical wiring because of their excellent conductivity. The versatility of alloys allows engineers and manufacturers to tailor materials for specific purposes, achieving optimal performance and efficiency.

How are the alloys made?

Alloys are produced through a process that involves the combination of two or more elements, at least one of which is a metal. The creation of alloys requires expertise and precision, often performed by alloy suppliers who specialize in alloy production.

The process of alloy formation typically begins with the selection of suitable metals or elements based on the desired properties of the final alloy. These metals or elements are carefully measured and combined in specific proportions to achieve the desired composition.

Alloy suppliers play a crucial role in ensuring the quality and consistency of the alloy. They employ various methods such as melting, mixing, and controlled cooling to create a homogenous mixture of the constituent elements. Melting the metals at high temperatures allows for thorough mixing and diffusion of atoms, resulting in a uniform distribution of the alloying elements.

Once the mixture is molten and well-mixed, it is solidified through controlled cooling. This solidification process is crucial in determining the microstructure and properties of the alloy. Rapid cooling can lead to the formation of fine-grained structures, while slower cooling allows for the development of larger crystal structures.

Alloy suppliers possess extensive knowledge and experience in managing the various parameters during the alloy production process. They carefully monitor factors such as temperature, cooling rate, and alloy composition to achieve the desired alloy properties consistently.

After solidification, the alloy may undergo additional treatments such as heat treatment, annealing, or mechanical processing to further enhance its properties. These steps are performed to optimize the alloy’s strength, hardness, ductility, or other specific characteristics based on the intended application.

In conclusion, the process of alloy production involves the expertise and precision of alloy suppliers who carefully select, combine, and control the various factors to create alloys with specific compositions and desired properties. Their knowledge and experience ensure the consistent production of high-quality alloys for various industries and applications.

What are the four classification of alloys?

Alloys can be classified into four main categories based on the base metal they are composed of copper alloys, aluminum alloys, iron alloys, and nickel alloys. These classifications are significant in the field of alloy production, where alloy suppliers play a crucial role.

Copper Alloys: Copper alloys are a group of alloys where copper serves as the base metal. These alloys often contain other elements such as zinc, tin, aluminum, or nickel. Copper alloys are widely used in various industries due to their excellent conductivity, corrosion resistance, and malleability. Alloy suppliers specializing in copper alloys carefully select and combine the appropriate elements to achieve desired properties for specific applications.

Aluminum Alloys: Aluminum alloys consist primarily of aluminum as the base metal. They are created by alloying aluminum with other elements such as copper, magnesium, zinc, or manganese. Aluminum alloys are valued for their low density, high strength-to-weight ratio, and corrosion resistance. Alloy suppliers specializing in aluminum alloys ensure precise control over the alloy composition and processing conditions to produce alloys with tailored properties for industries such as aerospace, automotive, and construction.

Iron Alloys: Iron alloys, also known as ferrous alloys, are alloys where iron is the base metal. These alloys include various combinations of iron with carbon and other elements such as chromium, nickel, or manganese. Iron alloys, such as steel and cast iron, exhibit exceptional strength, durability, and magnetic properties. Alloy suppliers specializing in iron alloys utilize advanced metallurgical techniques to produce alloys with specific properties suitable for applications ranging from structural components to industrial machinery.

Nickel Alloys: Nickel alloys are alloys that have a significant amount of nickel as the base metal. These alloys often contain other elements such as chromium, iron, molybdenum, or cobalt. Nickel alloys possess excellent resistance to corrosion, heat, and high-stress environments. Alloy suppliers specializing in nickel alloys employ precise alloying techniques and advanced manufacturing processes to create alloys with superior properties for critical applications in aerospace, chemical processing, and power generation.

The classifications based on the base metal serve as a guide for alloy suppliers to specialize in specific alloy types. Their expertise in selecting the right combination of elements and controlling the manufacturing process ensures the production of high-quality alloys that meet the stringent requirements of various industries.

What are 5 characteristics of alloy?

- Increased Hardness: Alloys are generally harder than their constituent metals. The addition of alloying elements or the formation of different crystal structures in alloys can enhance their hardness and strength. This makes alloys suitable for applications where high strength and durability are required.

- Improved Corrosion Resistance: Alloys often exhibit better resistance to corrosion compared to pure metals. The presence of alloying elements can form protective layers or compounds that act as barriers against corrosive agents. This makes alloys more suitable for use in environments where corrosion is a concern.

- Enhanced Durability: Alloys are designed to be more durable than the individual metals they are made from. By combining different metals or elements, the resulting alloy can possess improved mechanical properties, such as increased toughness, fatigue resistance, and wear resistance. This ensures that alloys can withstand harsh conditions and have a longer lifespan.

- Varied Electrical Conductivity: The electrical conductivity of alloys can vary depending on their composition and structure. While some alloys may have lower electrical conductivity compared to pure metals, others may exhibit enhanced conductivity. This versatility allows for the use of alloys in a wide range of electrical and electronic applications, where specific electrical properties are desired.

- Tailored Physical and Chemical Properties: Alloys offer the advantage of having their properties tailored to meet specific requirements. By carefully selecting and combining different metals or elements, engineers can create alloys with desired characteristics such as high-temperature resistance, magnetic properties, ductility, or thermal conductivity. This versatility allows for the customization of alloys for various industrial applications.

What is the difference between metal and alloy?

Metal and alloy are related terms, but they have distinct differences:

Metal: Metal refers to a chemical element that is typically solid, shiny, and a good conductor of heat and electricity. Metals have specific properties such as malleability (ability to be hammered or pressed into shapes), ductility (ability to be drawn into wires), and high thermal and electrical conductivity. Examples of metals include iron, aluminum, copper, gold, and silver.

Alloy: An alloy is a mixture or combination of two or more elements, at least one of which is a metal. Alloys are formed by blending different elements to create a new material with enhanced properties or to achieve specific characteristics not found in the individual constituent metals alone. The alloying elements can be other metals or non-metals. Alloys often exhibit properties such as improved hardness, corrosion resistance, strength, or specific functionality.

In summary, while metal refers to a single chemical element with characteristic properties, an alloy is a mixture of multiple elements, at least one of which is a metal. Alloys are created by combining metals or adding non-metallic elements to achieve desired properties, whereas metals exist as pure elements. Alloys offer a wide range of applications and advantages over pure metals, such as increased strength, improved corrosion resistance, and tailored properties.

Are alloys magnetic?

Alloys can exhibit a range of magnetic properties depending on their composition and structure. Some alloys are magnetic, while others are non-magnetic.

Ferromagnetic Alloys: Ferromagnetic alloys are alloys that are strongly attracted to magnets and can be magnetized. Examples of ferromagnetic alloys include iron-nickel (e.g., permalloy) and iron-cobalt (e.g., Alnico). These alloys contain a high concentration of ferromagnetic elements, which align their magnetic moments in the presence of a magnetic field.

Paramagnetic Alloys: Paramagnetic alloys are alloys that are weakly attracted to magnets. They exhibit a temporary magnetic response when exposed to a magnetic field but lose their magnetism when the field is removed. Some stainless steel alloys, which contain iron with additions of chromium and nickel, can exhibit paramagnetic behavior.

Diamagnetic Alloys: Diamagnetic alloys are alloys that are not attracted to magnets and have a weak negative magnetic susceptibility. They exhibit a repulsive force when placed in a magnetic field. Examples of diamagnetic alloys include copper alloys, aluminum alloys, and most non-magnetic stainless steel alloys.

It’s important to note that the magnetic properties of an alloy can also depend on factors such as temperature, crystal structure, and the specific composition of the alloying elements. Additionally, there are also alloys that can exhibit complex magnetic behavior, such as exhibiting both ferromagnetic and paramagnetic properties at different temperatures or under specific conditions.

In conclusion, while some alloys can be magnetic, the magnetic behavior of an alloy is determined by its specific composition and structure.

Alloy Suppliers

Why Choose Alloyours

As a leading alloy supplier in China, we understand the critical role that quality, affordability, and reliability play in your alloy procurement process. We are thrilled to present the reasons why choosing us as your trusted partner is the ideal solution for your needs.

Extensive Product Range

We boast an extensive portfolio of alloy products, encompassing a wide variety of metals, compositions, and specifications. Whether you require copper alloys, aluminum alloys, iron alloys, nickel alloys, or other specialized alloys, we have a comprehensive range to fulfill your diverse needs.

Exceptional Quality Control

Our rigorous quality control procedures are implemented at every stage of the manufacturing and supply chain processes. We source materials from reputable alloy suppliers, employ cutting-edge testing methods, and adhere to strict quality management systems.

Efficient Logistics and Timely Delivery

We understand the value of minimizing downtime and maximizing productivity, and our commitment to efficient logistics ensures that you can rely on us for seamless and on-time deliveries.