Stainless steel bar supplier

Alloyours Stainless Steel Bar Supplier offers a diverse range of stainless steel bars, including popular alloy grades like 304, 304L, and 316L. Our bars come in various finishes, such as cold drawn, centerless ground, hot, and mill finishes, providing versatile options for your specific needs.

Our stainless steel bars cater to a wide range of industries, including automotive, aerospace, food service, chemical, marine, and more. At Alloyours, we take pride in offering quality stainless steel bars tailored to your exact specifications, ensuring reliability and performance in your industrial applications.

Stainless Steel bar Supplier

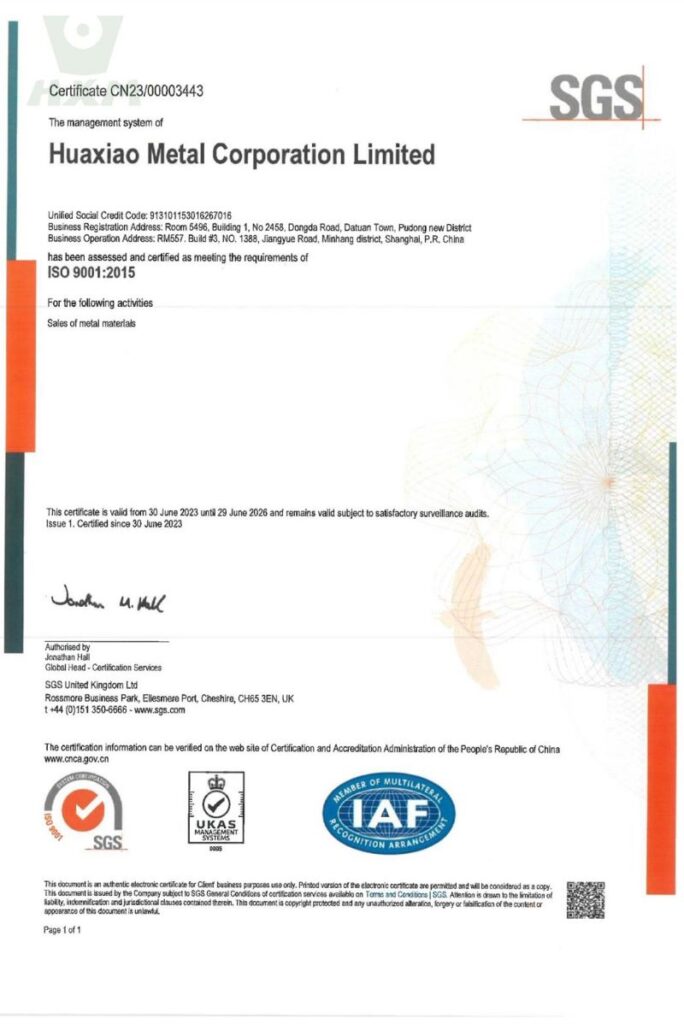

our partners

Stainless Steel bar Supplier

Why choose us

Extensive Selection

Choose from a wide range of sizes, grades, and finishes to meet your specific needs.

Premium Quality

We provide top-notch stainless steel bars known for their quality and durability.

Expertise and Experience

Benefit from our industry expertise and years of experience.

Efficient After-Sales Support

We’re here to assist you even after your purchase.

Welcome to Alloyours, your premier destination for top-quality stainless steel solutions.

We are a leading alloy metal supplier known for our unwavering commitment to quality, innovation, and customer satisfaction. With a wide range of products, customization options, and a strong focus on sustainability, we provide the stainless steel materials and expertise you need to excel in your projects.

Stainless Steel bar Supplier

What Our Clients Say

FAQ

Frequently Asked Questions About Stainless Steel Quotes

Get quick answers to your most pressing questions about stainless steel quotes.

To request a quotation, please feel free to contact us in one of the following ways:

Online Inquiry Form: You can fill out the online inquiry form on our website (at the bottom of the page) to provide detailed information about your specific requirements for stainless steel sheet and plate. We will get back to you with a quote in a timely manner.

Email: Send an email to market004@alloyours.com including your project specifications and any questions. Our team will provide you with a detailed quote and further assistance.

WhatsApp: Add +86 13052085117. Our friendly and knowledgeable customer support team is ready to provide you with advice and a quick quote.

Absolutely, we offer custom sizes and special processing services to meet your project’s unique requirements. Whether you need stainless steel bar in non-standard dimensions or specialized processing such as cutting, shaping, or finishing, we have the capabilities to accommodate your requests.

Product delivery times may vary depending on several factors, including the specific stainless steel product, quantity, customization requirements, and your location. However, we are committed to providing you with accurate delivery estimates to ensure your project stays on schedule.

To get precise delivery times for your order, please reach out to us with your project details, including the stainless steel product type, quantity, customization needs, and your location. Our customer support team will promptly provide you with a delivery timeline based on your unique requirements.

Stainless Steel bar Supplier

How is stainless steel bar made?

The production process of stainless steel bars involves several key steps to ensure the creation of high-quality and durable products:

Raw Material Sourcing

The process begins with sourcing raw materials like iron ore, chromium, nickel, and other essential elements required for stainless steel production.

Melting

These raw materials are carefully measured and melted in a large electric furnace. The intense heat, applied for an extended period, transforms the raw materials into a molten state.

Forming and Shaping

The molten metal is then shaped and formed into the desired bar profile. Various methods, including hot rolling, cold rolling, extrusion, or forging, are employed to achieve the desired shape and dimensions.

Heat Treatment

To enhance the stainless steel's mechanical properties, such as strength and durability, heat treatment is often applied. This step optimizes the material for specific applications.

Surface Treatment

Surface treatments like pickling and passivation are performed. Pickling removes contaminants and impurities from the surface, while passivation promotes the formation of a protective chromium-oxide layer, enhancing corrosion resistance.

Quality Control

Throughout the production process, strict quality control measures are implemented to ensure that the stainless steel bars meet the required specifications and standards.

Final Product

The finished stainless steel bars are then ready for distribution and use in a wide range of applications across various industries.

Stainless Steel bar Supplier

types of stainless steel bar

- Round Bar/Rod: These bars are characterized by their circular cross-section and are sized by their diameter. Round bars are widely used in the manufacturing of machine parts, fasteners, and shafts due to their excellent strength and corrosion resistance.

- Flat/Rectangular Bar: Flat bars have a flat, rectangular shape and are sized by their thickness and width. They are commonly used in the construction of structures, frames, and supports, where a flat, load-bearing surface is required.

- Square Bar: Square bars have a square cross-section and can be sized by either their thickness or width. They are often used in applications requiring a combination of strength and aesthetics, such as architectural elements and decorative fixtures.

- Hexagonal Bar: Hexagonal bars have a six-sided, hexagonal cross-section and are sized by the distance between opposite flat faces. They are popular in industries requiring precision machining, such as aerospace and automotive, for producing bolts, nuts, and fittings.

- Angle Bar: Angle bars have an L-shaped cross-section, with two legs at a right angle. They are used in construction, frames, and supports to provide structural strength and stability while allowing for various angles and connections.

Stainless Steel bar Supplier

How to cut stainless steel bar?

Cutting a stainless steel bar efficiently depends on the thickness and the available tools. Alloyours stainless steel bar supplier recommends several methods:

Hacksaw

For thinner bars, a hacksaw provides a straightforward cutting solution.

Miter Saw

Ideal for precision cuts, a miter saw is excellent when dealing with stainless steel bars.

Band Saw

For efficient and clean cuts, a band saw is a versatile choice.

Angle Grinder

When dealing with thicker bars, an angle grinder equipped with a metal cut-off wheel gets the job done.

Plasma Cutter

To cut very thick bars or solid tubes, a plasma cutter offers speed and precision.

Waterjet Cutter

A waterjet cutter provides precise cuts and is suitable for various bar sizes.

Oxy-Acetylene Torch

An oxy-acetylene torch can cut through stainless steel effectively.

Laser Cutter

For clean and precise cuts, a laser cutter is a high-tech option.

Always prioritize safety when cutting stainless steel bars, using proper gear like gloves and eye protection. Trust Alloyours, your stainless steel bar supplier, for quality materials and guidance in choosing the right method for your project.

Contact Us

Contact us for a quote

Minhang District

Shanghai, China

Email:

market004@alloyours.com

Phone:

+ 86 13052085117