how to cut copper pipe?

Welcome to the realm of copper craftsmanship, where precision and scientific principles converge to unlock the art of cutting copper pipe. Whether you’re a seasoned professional or a curious DIY enthusiast, understanding the fundamental principles behind this process is crucial for achieving impeccable results.

The scientific intricacies of cutting copper pipe encompass aspects such as applied force, metal properties, and heat dissipation. By harnessing these principles, you can optimize your cutting technique, minimize wastage, and achieve clean, accurate cuts every time.

In this enlightening guide, we will unravel the scientific secrets behind cutting copper pipe. We will explore the mechanical properties of copper, examining how its malleability and conductivity impact the cutting process. Additionally, we will uncover the interplay between tool design, applied force, and friction to ensure precise and efficient cuts.

How to Cut Copper Pipe?

- Measure and mark the desired length using a tape measure and pencil.

- Choose the appropriate cutting tool: a hacksaw, pipe cutter, or tubing cutter.

- Secure the pipe in a vise or with a pipe-cutting guide.

- For a hacksaw, align the blade with the marked line and make slow, steady strokes.

- For a pipe cutter, tighten the cutter around the pipe, rotate it, and tighten it after each rotation.

- For a tubing cutter, position the cutter wheel on the mark, tighten it, and rotate the cutter around the pipe.

- Repeat the cutting process until the pipe is severed.

- File any rough edges or use a deburring tool to smooth them.

- Clean the pipe before installation. Remember to wear protective gear and work in a well-ventilated area.

The Scientific Foundations of Cutting Copper Pipe

Physics of metalworking and its application to cut copper Pipe

When it comes to cutting copper pipes, an understanding of the physics of metalworking is crucial. Copper, being a malleable metal, responds to the applied force and can be shaped with precision. The principles of force, pressure, and motion come into play during the cutting process. By harnessing these physics concepts, alloy suppliers can manipulate copper pipes to achieve the desired shapes and sizes. This knowledge allows for efficient material removal and reduces the risk of damage or deformation to the pipe.

Engineering principles governing the cutting process

Cutting copper pipe involves the application of engineering principles that ensure accurate and clean cuts. Factors such as the choice of cutting tool, speed, and technique directly impact the quality of the cut. Engineering principles, such as mechanical advantage, leverage, and tool design, come into play when selecting the most suitable tool for the job. By understanding these principles, alloy suppliers can optimize the cutting process, minimize wastage, and achieve precise cuts consistently.

Essential Tools for Cutting Copper Pipe

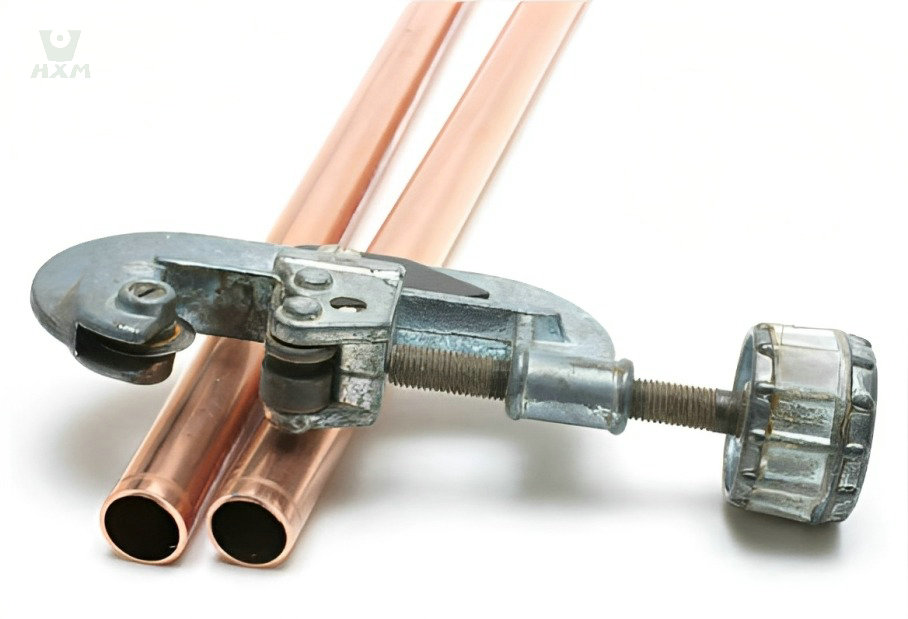

pipe cutters, tubing cutters, and hacksaws

When it comes to cutting copper pipe, several tools can get the job done effectively. Pipe cutters, tubing cutters, and hacksaws are commonly used in copper-cutting projects. Pipe cutters are designed specifically for cutting pipes, providing precise and clean cuts. Tubing cutters, on the other hand, are ideal for cutting smaller-diameter copper tubes with accuracy. Hacksaws offers a versatile option for cutting copper pipe, allowing for more flexibility in different cutting scenarios.

Technological Advancements and Benefits

Over the years, pipe cutters, tubing cutters, and hacksaws have undergone remarkable technological advancements, revolutionizing the process of cutting copper pipe. These tools offer a range of benefits that enhance precision, efficiency, and overall cutting experience.

Pipe Cutters

Pipe cutters have undergone significant technological advancements, resulting in enhanced performance, efficiency, and convenience. These advancements have transformed the cutting experience for copper pipe suppliers and DIY enthusiasts working with copper pipes.

Technological Advancements:

- Adjustable Blades: Modern pipe cutters feature adjustable blades that allow for precise depth control. This enables craftsmen to achieve clean and accurate cuts while minimizing the risk of pipe deformation.

- Ratcheting Mechanisms: Some pipe cutters are equipped with ratcheting mechanisms that provide consistent pressure during the cutting process. This ensures smooth and controlled cutting motion, reducing the effort required.

- Ergonomic Designs: Pipe cutters now come with ergonomic handle designs, providing a comfortable grip and reducing hand fatigue during prolonged use. This allows for improved control and maneuverability while cutting.

Benefits:

- Clean and Burr-Free Cuts: Pipe cutters excel at delivering clean, burr-free cuts, eliminating the need for extensive filing or deburring. This results in precise, professional-looking cuts and facilitates smooth connections during installations.

- Time and Effort Savings: The efficient cutting action of pipe cutters enables quick and accurate cuts, saving both time and effort. This is particularly advantageous when working on projects with multiple cuts or tight deadlines.

- Versatility: Pipe cutters are available in various sizes, allowing for versatility in cutting different pipe diameters. They are suitable for both small-scale and large-scale projects, making them indispensable tools for copper pipe suppliers in various industries.

The technological advancements in pipe cutters have revolutionized the cutting process for copper pipes, providing craftsmen with tools that are more precise, efficient, and user-friendly. With adjustable blades, ratcheting mechanisms, and ergonomic designs, pipe cutters offer clean cuts, time savings, and versatility. These benefits make pipe cutters an essential tool for copper pipe suppliers and DIY enthusiasts, enabling them to achieve accurate and high-quality cuts in their copper pipe projects.

Oscillating multi-tools

Oscillating multi-tools have experienced remarkable technological advancements, revolutionizing the cutting process across various materials, including copper pipes. These versatile tools offer a wide range of benefits that make them invaluable for craftsmen and DIY enthusiasts alike.

Technological Advancements:

- Enhanced Power and Performance: Modern oscillating multi-tools feature more powerful motors, allowing for efficient cutting through various materials, including copper pipes. Increased oscillation speeds and higher torque ensure smoother and faster cutting.

- Quick-Change Systems: Many models now incorporate tool-free blade change systems, enabling swift and hassle-free swapping between different cutting blades, allowing for seamless transitions between tasks.

- Precision and Control: Oscillating multi-tools now come with adjustable speed settings, giving craftsmen better control over the cutting process. This allows for greater precision, especially when making intricate cuts or working with delicate copper pipes.

Benefits:

- Versatility: Oscillating multi-tools offer a wide range of applications beyond cutting. With interchangeable blades and accessories, they can handle tasks such as sanding, grinding, scraping, and plunge cutting. This versatility makes them a valuable addition to any toolkit.

- Accessibility: These tools excel in hard-to-reach areas and tight spaces where traditional cutting tools may struggle. Their compact design and maneuverability enable craftsmen to make precise cuts even in confined areas, making them highly suitable for intricate copper pipe projects.

- Reduced Vibration and Noise: Advancements in tool design and engineering have resulted in reduced vibration and noise levels during operation. This not only enhances comfort but also improves overall control and precision while cutting copper pipes.

Oscillating multi-tools have become indispensable for craftsmen working with copper pipes. The technological advancements and benefits offered by these tools, such as increased power, precision, versatility, and accessibility, have elevated the cutting experience. Whether it’s making straight cuts, notches, or intricate patterns, oscillating multi-tools provide the convenience and efficiency needed to achieve professional-quality results in copper pipe projects.

Hacksaws

Hacksaws, a versatile cutting tool, has undergone notable technological advancements, enhancing their performance and making them even more valuable for cutting various materials, including copper pipes. These advancements have brought forth several benefits that cater to the needs of copper pipe suppliers and DIY enthusiasts.

Technological Advancements:

- Improved Blade Materials: Hacksaw blades have witnessed advancements in materials, such as high-speed steel or bi-metal, resulting in improved cutting efficiency and durability. These blades retain their sharpness for longer periods, ensuring smoother and more precise cuts.

- Enhanced Blade Design: Hacksaw blades now feature optimized tooth geometries, allowing for more efficient cutting action. This design improvement reduces blade binding and enhances cutting performance, resulting in cleaner and faster cuts.

- Ergonomic Handle Designs: Hacksaws have embraced ergonomic handle designs, providing a comfortable and secure grip. These designs reduce hand fatigue and enhance control, enabling copper pipe suppliers to make precise and controlled cuts.

Benefits:

- Versatility: Hacksaws offer versatility in cutting various pipe sizes and materials, including copper pipes. They can handle different cutting scenarios, making them a practical tool for a wide range of projects.

- Flexibility in Tight Spaces: Hacksaws excel in situations where space constraints limit the use of other cutting tools. Their compact size and maneuverability allow copper pipe suppliers to navigate confined areas and make accurate cuts, ensuring successful outcomes in challenging environments.

- Budget-Friendly Option: Compared to specialized cutting tools, hacksaws are often more budget-friendly. They offer an economical cutting solution without compromising on the quality of the cuts.

The technological advancements in hacksaws have elevated their performance and usability, offering copper pipe suppliers and DIY enthusiasts numerous benefits. With improved blade materials, optimized tooth geometries, and ergonomic handle designs, hacksaws deliver efficient and precise cutting results. Their versatility, adaptability to tight spaces, and cost-effectiveness make hacksaws a reliable and accessible tool for cutting copper pipes and other materials.

Scientific Techniques for Cutting Copper Pipe

When cutting copper pipe, it is essential to understand the scientific principles of applied force, friction, and heat transfer, as they play a significant role in the cutting process and its effectiveness.

Applied Force

Applied force refers to the pressure exerted on the cutting tool, such as a hacksaw or a pipe cutter, to initiate and maintain the cutting action. By applying force in a controlled manner, copper pipe suppliers can create the necessary contact between the tool and the copper pipe, allowing for material removal. The magnitude and direction of the applied force impact the cutting speed and the quality of the cut. Too little force may result in slow progress, while excessive force can cause damage to the pipe or the cutting tool. Understanding the optimal amount of applied force ensures efficient and successful cuts.

Friction

Friction is the resistance encountered between the cutting tool and the surface of the copper pipe during the cutting process. As the tool moves against the pipe, friction generates heat and wears away the material. This interaction between the tool and the pipe’s surface determines the cutting efficiency and the smoothness of the cut. By minimizing friction through the use of sharp blades, lubricants, or cooling methods, copper pipe suppliers can reduce heat buildup and prevent the pipe from becoming deformed or damaged during the cutting process.

Heat Transfer

Heat transfer occurs as a result of the friction between the cutting tool and the copper pipe. As the tool’s blade moves across the pipe’s surface, the friction generates heat, softening the metal and aiding in the cutting action. Heat transfer plays a crucial role in making the cutting process more effective and efficient, as it helps to reduce the hardness of the metal, making it easier to cut. However, excessive heat can also be detrimental, leading to overheating, warping, or damaging the pipe. Managing heat transfer by monitoring cutting speed, using appropriate cooling methods, or periodically pausing to allow the pipe to cool ensures optimal cutting conditions and prevents unwanted consequences.

By understanding the scientific principles of applied force, friction, and heat transfer, copper pipe suppliers can optimize their cutting techniques when working with copper pipes. Applying the right amount of force, minimizing friction, and managing heat transfer contribute to achieving clean, precise cuts while maintaining the integrity of the pipe. These scientific principles serve as a guide for craftsmen and copper pipe suppliers, ensuring successful cutting outcomes and delivering high-quality products to their customers.

Safety Precautions and Protocols

Importance of Prioritizing Safety

When cutting copper pipes, prioritizing safety is paramount. The cutting process involves sharp tools and potential hazards that can cause injury if proper precautions are not taken. By placing safety at the forefront, copper pipe suppliers can protect themselves and others while ensuring a smooth and accident-free workflow. Prioritizing safety not only reduces the risk of injuries but also promotes a professional and responsible approach to copper crafting.

Essential Protective Measures

Eye Protection

Eye injuries can occur due to flying debris, metal shards, or accidental contact with the cutting tool. It is crucial to wear safety goggles or face shields that provide adequate eye protection throughout the cutting process.

Hand Protection

As hands are in close proximity to the cutting area, they are vulnerable to cuts, abrasions, or burns. Wearing sturdy work gloves that offer cut resistance and a firm grip enhances hand safety and minimizes the risk of accidents.

Respiratory Protection

When cutting copper pipes, the release of dust or particles may pose respiratory risks. Using a respirator or a dust mask protects the airways from harmful particles, ensuring a safer working environment.

Overall Well-being

Adequate personal protective equipment (PPE), such as appropriate clothing and footwear, should be worn to protect against potential injuries and minimize the risk of slips, trips, or falls. Additionally, maintaining good posture, taking regular breaks, and staying hydrated contributes to overall well-being during the cutting process.

Ensuring a Safe Working Environment

Creating a safe working environment is crucial for copper crafting. Some key steps to ensure a safe working environment include:

Proper Lighting

Adequate lighting reduces the risk of accidents by enhancing visibility, allowing craftsmen to work with precision and clarity.

Clear Workspace

A clutter-free workspace reduces the chances of tripping or accidentally knocking over tools or materials. Keeping the area clean and organized promotes a safer and more efficient working environment.

Secure Workpiece

Securing the copper pipe firmly before cutting prevents it from moving or slipping, minimizing the risk of accidents and ensuring cleaner cuts.

Training and Education

Providing proper training and education on safe cutting techniques, tool operation, and handling of materials promotes a culture of safety among craftsmen. Regular safety meetings and updates reinforce safe practices and awareness.

By implementing these safety precautions and protocols, craftsmen can create a safe working environment, safeguard themselves and others from potential hazards, and promote a culture of safety in copper crafting. Prioritizing safety measures ensures a smooth and accident-free cutting process, allowing craftsmen to focus on producing high-quality copper products with peace of mind.

Conclusion

Throughout this article, we have delved into the scientific foundations, technological advancements, and safety considerations involved in cutting copper pipes. We explored the physics of metalworking, engineering principles, and the role of applied force, friction, and heat transfer in the cutting process. We also highlighted the technological advancements and benefits of tools such as pipe cutters, tubing cutters, hacksaws, and oscillating multi-tools. Additionally, we emphasized the importance of prioritizing safety and maintaining a safe working environment during copper crafting endeavors.

Armed with this newfound knowledge, it is crucial for craftsmen and copper pipe suppliers to apply these techniques and principles in their copper crafting endeavors. By incorporating scientific precision and utilizing advanced cutting tools, they can enhance the quality, efficiency, and accuracy of their work. Furthermore, by prioritizing safety measures and creating a safe working environment, they can protect themselves and others, ensuring a positive and secure copper crafting experience.

In the world of copper crafting, there is a beautiful synergy between artistry and scientific precision. The blending of craftsmanship, creativity, and a deep understanding of the scientific principles involved in cutting copper pipes elevates the quality and craftsmanship of the final products. By embracing this synergy, craftsmen can produce exquisite copper works while maintaining the highest standards of precision and efficiency.

As craftsmen and copper pipe suppliers continue to explore and apply scientific techniques, utilize advanced tools, and prioritize safety, they will establish themselves as leaders in the industry. By consistently striving for excellence, combining artistry with scientific precision, and staying abreast of technological advancements, they will continue to deliver exceptional copper products that meet the needs and expectations of their customers.

Through the fusion of art and science, the journey of cutting copper pipe becomes not only a technical process but also a form of creative expression. Let us embrace this union and push the boundaries of craftsmanship, achieving remarkable results in the world of copper crafting.