-Alloyours copper alloy manufacturers

Have you ever held a metal object and wondered whether it’s copper or brass? Understanding the distinction between these two alloys can be both intriguing and practical. In this article, we will embark on a journey to decipher the subtle but significant differences between copper and brass.

What's the difference between copper and brass?

Distinguishing between copper and brass, two closely related alloys, requires attention to their distinct properties and appearances.

- Color: Copper boasts a reddish-brown hue, while brass has a brighter, more yellowish tint.

- Sound: When struck, copper produces a distinctive, melodious sound, often referred to as a "coppery" ring. Brass, on the other hand, generates a sharper, more metallic tone.

- Magnetism: Copper is not magnetic, whereas some brass alloys exhibit weak magnetic properties due to the presence of iron.

- Density: Brass is denser than copper due to the added zinc. You can gauge this by holding objects made from each material; brass items will feel heavier for their size compared to copper ones.

- Corrosion Resistance: Copper is known for its corrosion-resistant properties, often developing a greenish patina over time. Brass tarnishes differently, usually taking on a darker, more brownish patina.

By examining these factors, you can confidently differentiate between copper and brass, whether you’re dealing with coins, jewelry, or various metal objects.

Copper and brass are two versatile metals that have found their way into numerous aspects of our lives, from the coins in our pockets to the pipes in our homes. Now, let’s embark on this journey of metallurgical discovery and unveil the secrets of distinguishing copper from brass, with occasional insights into how copper alloy manufacturers craft these materials to serve various purposes.

What's is copper and brass?

Before we dive into the art of distinguishing copper from brass, it’s essential to grasp the fundamental nature of these metals. Copper and brass, although often confused due to their similar appearance, have distinct compositions and histories.

Copper and Brass as Alloys

Copper and brass are two distinct alloys with unique properties, primarily composed of copper. Understanding their compositions is vital in distinguishing them accurately.

Copper

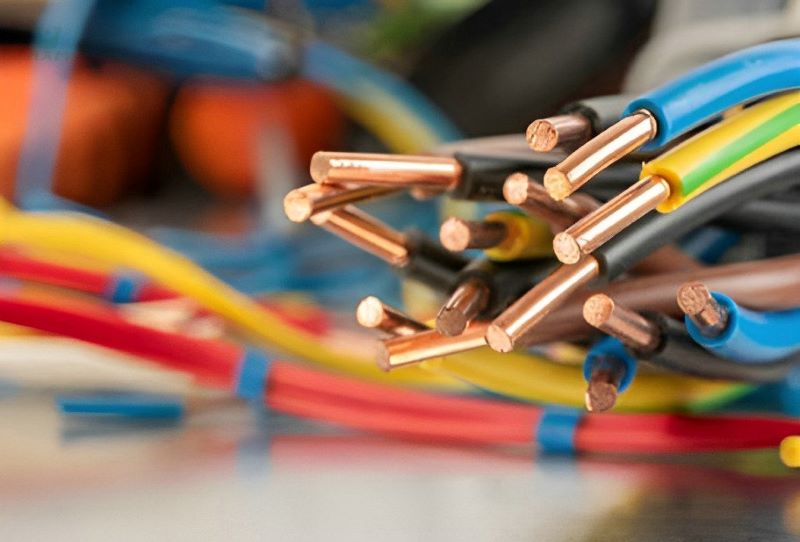

Copper is a pure elemental metal, a reddish-brown substance that exists in its unalloyed state. It’s an excellent conductor of electricity and heat, making it indispensable in electrical wiring, plumbing, and various industrial applications.

Brass

Brass, on the other hand, is a copper alloy. It’s crafted by mixing copper with varying amounts of zinc. This blending gives brass its characteristic yellowish appearance, distinct from pure copper’s reddish hue.

The proportion of zinc can be adjusted to produce brass with different properties, such as enhanced corrosion resistance or improved malleability. Copper alloy manufacturers carefully control the zinc content during the brass-making process to create specific brass variants, each tailored for particular applications. This deliberate alloying process is the key to brass’s versatility in diverse industries.

So, while copper remains unadulterated, brass represents the intriguing fusion of copper and zinc, offering a myriad of applications that set it apart from its elemental counterpart. Understanding these alloying differences is the first step in distinguishing between copper and brass.

Historical and Modern Applications of Copper and Brass

Copper and brass, as two distinct alloys with unique properties, have played pivotal roles in human history and continue to shape the modern world through a wide array of applications.

Copper

Historical Significance

- Ancient civilizations like the Egyptians, Greeks, and Romans recognized copper's value and used it for jewelry, tools, and coins.

- The Bronze Age marked a pivotal moment when copper was alloyed with tin to create bronze, revolutionizing weapons and tools.

Modern Applications

- Electrical Conductivity: Copper's exceptional electrical conductivity makes it indispensable in electrical wiring, power generation, and transmission.

- Plumbing: Copper's corrosion resistance and malleability make it the material of choice for water pipes and fittings.

- Renewable Energy: Copper is vital in renewable energy systems, such as solar panels and wind turbines, due to its efficiency in conducting electricity.

- Architecture: Copper roofing, facades, and ornaments add aesthetic appeal and durability to buildings.

-Alloyours copper alloy manufacturers

Brass

Historical Significance

- Brass production dates back to ancient civilizations like the Indus Valley and Mesopotamia.

- Brass has been used for coins, weaponry, and decorative items throughout history.

Modern Applications

- Musical Instruments: Brass instruments, such as trumpets and saxophones, are celebrated for their distinctive sound quality.

- Decorative Arts: Brass is commonly employed in jewelry, sculptures, and architectural embellishments.

- Plumbing and Fittings: Brass fixtures, valves, and fittings are valued for their corrosion resistance and reliability.

- Marine and Automotive: Brass alloys are used in ship propellers, automotive radiators, and engine components due to their resistance to saltwater corrosion.

-Alloyours copper alloy manufacturers

Copper alloy manufacturers have refined these alloys over millennia to cater to a multitude of modern needs, underscoring their enduring significance in both historical and contemporary contexts. Understanding their applications provides a foundation for distinguishing between copper and brass accurately.

Advanced Techniques for Identification

Distinguishing between copper and brass can sometimes require more advanced techniques, especially when visual inspection and basic tests are inconclusive. Two prominent methods for precise determination are composition analysis using X-ray fluorescence (XRF) and other sophisticated methods that delve deeper into material characteristics.

Composition Analysis using X-ray Fluorescence (XRF)

X-ray fluorescence is a powerful non-destructive technique used for determining the elemental composition of materials. It relies on the principle that when a sample is exposed to X-rays, it emits characteristic X-rays of different energies, providing information about the elements present. In the case of copper and brass, XRF can accurately determine the metal composition and identify trace elements, helping to differentiate between the two alloys.

Other Sophisticated Methods

Beyond XRF, several advanced techniques are available for material analysis. These include:

- Scanning Electron Microscopy (SEM): SEM offers high-resolution imaging and can reveal the microstructure and composition of materials at the microscopic level.

- Energy-Dispersive X-ray Spectroscopy (EDS): Coupled with SEM, EDS provides elemental analysis of small regions, aiding in material characterization.

- Spectroscopy: Techniques like Fourier Transform Infrared (FTIR) and Raman spectroscopy can provide information about molecular vibrations and chemical bonding, assisting in material identification.

These advanced methods, often available in specialized laboratories or industrial settings, are crucial when precise differentiation between copper and brass is required, especially for quality control, materials research, or historical artifact analysis.

Are there any simple tests to distinguish between copper and brass at home?

There are some simple tests that can be performed at home to distinguish between copper and brass:

- Visual Inspection: One of the easiest methods is visual inspection. Copper has a reddish-brown color, whereas brass is more yellowish. By comparing the color of the object to known copper and brass samples, you can often make a preliminary identification.

- Magnet Test: Copper is not magnetic, while some types of brass may exhibit weak magnetic properties. Using a strong magnet, you can check if the object is attracted to it. If it is, it's more likely to be brass.

- Density Test: Brass is denser than copper. You can compare the weight of the object to its volume to estimate its density. If it's denser than copper, it's probably brass.

- Sound Test: Tap the object and listen to the sound it produces. Brass tends to produce a higher-pitched, more musical sound compared to copper, which typically has a lower-pitched sound.

- Acid Test: Although this is a bit more involved, you can apply a mild acid (like vinegar) to a small, inconspicuous area of the object. Copper will not react, while brass will produce a greenish patina due to the zinc content. Be cautious with this method, as it can damage the object's surface.

- Scratch Test: Use a file or a sharp object to make a small scratch in an inconspicuous area. Observe the color of the scratch. If it's reddish-brown like copper, the object is likely copper. If it's yellowish, it's probably brass.

Remember that these tests are not foolproof and may not work in all cases, especially if the object is coated or plated. For precise identification, it’s best to consult professional and copper alloy manufactures or use more advanced techniques like X-ray fluorescence (XRF) analysis, which can determine the exact composition of the material, including the presence of various metals like zinc in brass. Copper alloy manufacturers may also provide guidance on identifying their products accurately.

Is there a risk of mistaking copper for brass or vice versa in recycling efforts?

In recycling efforts, there is indeed a potential risk of mistaking copper for brass or vice versa due to their similar appearances, which can lead to suboptimal recycling outcomes. Here’s why:

- Visual Similarity: Copper and brass have similar visual characteristics, with both exhibiting a reddish-brown to yellowish color. This visual similarity can make it challenging to differentiate between the two metals by sight alone.

- Mixed Alloys: In many recycled products or scrap materials, copper and brass may be combined. These mixed alloys are challenging to separate accurately without proper identification.

- Alloy Variations: There are various types of brass alloys with differing copper and zinc compositions, making it even more challenging to identify them precisely during recycling.

To mitigate the risk of mistaking copper for brass or vice versa in recycling, various methods and technologies can be employed:

- Advanced Sorting Techniques: Recycling facilities often use advanced sorting equipment, such as X-ray fluorescence (XRF) machines, to precisely identify the composition of materials. These machines can differentiate between copper and brass and sort them accordingly.

- Manual Sorting: Skilled workers in recycling facilities can visually identify and manually sort copper and brass materials. This process requires trained personnel to recognize the subtle differences in color and physical characteristics.

- Chemical Analysis: Some recycling operations may use chemical tests to distinguish between copper and brass, but this is less common due to the time and resources required.

- Consulting Copper Alloy Manufacturers: Copper alloy manufacturers can provide guidance on identifying their specific products. They may have proprietary markings or unique characteristics that aid in accurate identification.

In conclusion, while there is a risk of mistaking copper for brass or vice versa in recycling efforts, recycling facilities employ various methods and technologies to minimize this risk and ensure the efficient separation and recycling of these valuable materials. Consulting copper alloy manufacturers and utilizing advanced sorting techniques are key steps in accurate metal identification during recycling processes.

How does the electrical conductivity of copper compare to that of brass?

The electrical conductivity of copper and brass differs significantly due to their distinct compositions:

Copper’s Electrical Conductivity: Copper is renowned for its exceptional electrical conductivity. It is one of the best conductors among all naturally occurring elements. The electrical conductivity of pure copper is approximately 58.5 x 10^6 Siemens per meter (S/m). This high conductivity makes copper a preferred material for electrical wiring, circuits, and various electrical components.

Brass’s Electrical Conductivity: Brass, on the other hand, is an alloy composed primarily of copper and zinc. The introduction of zinc significantly reduces its electrical conductivity compared to pure copper. The electrical conductivity of brass varies depending on its zinc content and other alloying elements, but it typically falls within a range of 15 to 40 MS/m (megasiemens per meter). This is significantly lower than that of pure copper.

In practical terms, the lower electrical conductivity of brass makes it less suitable for applications where high electrical conductivity is essential, such as electrical wiring and power transmission. Instead, copper, with its superior conductivity, remains the material of choice for such applications.

Copper alloy manufacturers, including brass, carefully control the alloying elements and their proportions to achieve specific characteristics, including electrical conductivity. This allows them to tailor the properties of the alloy to meet the requirements of various applications, striking a balance between electrical conductivity and other desirable traits like corrosion resistance and machinability.

conclusion

In conclusion, the ability to distinguish between copper and brass is a valuable skill, given the prevalence of these metals in our daily lives. Here, we’ve explored the fundamental differences in color, density, magnetic behavior, sound, corrosion resistance, and conductivity that set these alloys apart. These distinctions can be crucial in various contexts, from recycling and metallurgy to antique appraisal and industrial applications.

Precise identification ensures the appropriate use, recycling, and maintenance of copper and brass items, contributing to both resource conservation and the preservation of their unique properties. When in doubt, consulting copper alloy manufacturers or employing advanced analytical techniques can provide definitive answers in cases where visual or basic tests fall short. Armed with this knowledge, individuals and industries alike can make informed decisions about these versatile metals, optimizing their utility and environmental impact.