-Alloyours aluminum alloy manufacturers

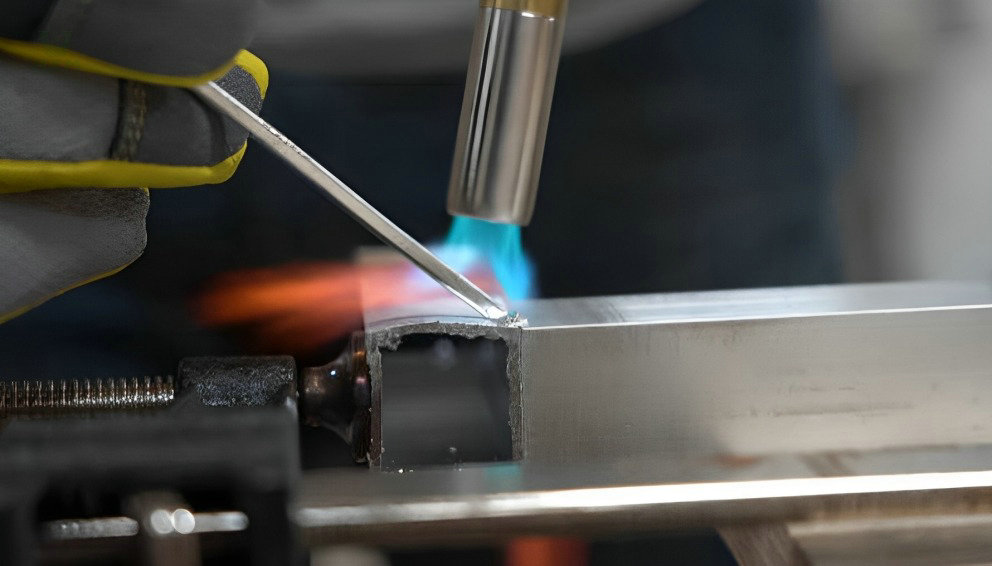

As you gaze upon the gleaming body of a modern car or admire the latticed structure of an aircraft wing, you’re likely looking at aluminum craftsmanship. Aluminum is a lightweight, durable, and corrosion-resistant metal that’s become an integral part of countless industries. But have you ever wondered how those intricate aluminum structures are meticulously crafted? The answer lies in welding. Welding aluminum can be a complex task, but it’s an essential skill for fabricating everything from vehicles to kitchen utensils.

In this blog, you’ll learn about the different welding methods, necessary equipment, and crucial techniques to join this versatile metal effectively. Let’s dive into the world of aluminum welding and discover how you can turn this lightweight metal into the backbone of modern engineering and design.

how to weld aluminium?

Weld aluminium is a precise science that demands the right techniques and equipment. Aluminum’s high thermal conductivity and low melting point make it challenging to weld using traditional methods. TIG (Tungsten Inert Gas) welding, and MIG (Metal Inert Gas) welding are two primary methods for joining aluminum.

Proper cleaning and surface preparation are crucial before welding aluminum. Any oxide layer on the metal’s surface should be removed. A specialized aluminum wire and gas mix are required for MIG welding, while TIG welding utilizes a pure argon shielding gas.

Heat control and travel speed are essential during aluminum welding, as overheating can lead to distortion and weak welds. Using the correct filler material matched to the base alloy is also crucial.

The Unique Challenges of Welding Aluminum

Aluminum welding stands apart from other welding processes due to the unique challenges it presents. Understanding these hurdles is essential for successful welding:

- Oxide Layer: Aluminum naturally forms a thin oxide layer on its surface, which melts at a much higher temperature than aluminum itself. This oxide layer must be meticulously removed during welding to ensure a sound bond.

- High Thermal Conductivity: Aluminum has high thermal conductivity, which makes it exceptionally efficient at dissipating heat. This feature necessitates a precise control of heat input during welding.

- Low Melting Point: While aluminum has a lower melting point compared to some other metals, its high thermal conductivity requires even more heat during welding. However, this can lead to distortion and burn-through if not managed properly.

- Porosity: While aluminum has a lower melting point compared to some other metals, its high thermal conductivity requires even more heat during welding. However, this can lead to distortion and burn-through if not managed properly.

- Cracking: Aluminum welding can lead to cracking if not executed carefully. Proper joint design and filler materials are critical to prevent cracks from forming.

The Importance of Mastering Aluminum Welding Techniques

Mastering aluminum welding techniques is indispensable for several reasons:

- Wider Applications: Aluminum's use in various industries, such as aerospace, automotive, and marine, underscores the need for skilled aluminum welders. Proficiency in aluminum welding broadens your career prospects.

- Enhanced Structural Integrity: Precise aluminum welding ensures the structural integrity of welded components. This is especially crucial in critical applications where strength and safety are paramount.

- Cost Savings: Skillful aluminum welding minimizes the likelihood of weld defects and rework, leading to cost savings in materials and labor.

- Environmental Benefits: Effective aluminum welding results in fewer material wastages and reduced energy consumption, contributing to a more sustainable welding process.

About aluminium

Before delving into how to weld aluminium, it’s crucial to develop a comprehensive understanding of this remarkable metal. In this section, we will explore the properties, characteristics, and various alloys used in aluminum welding.

what is aluminum?

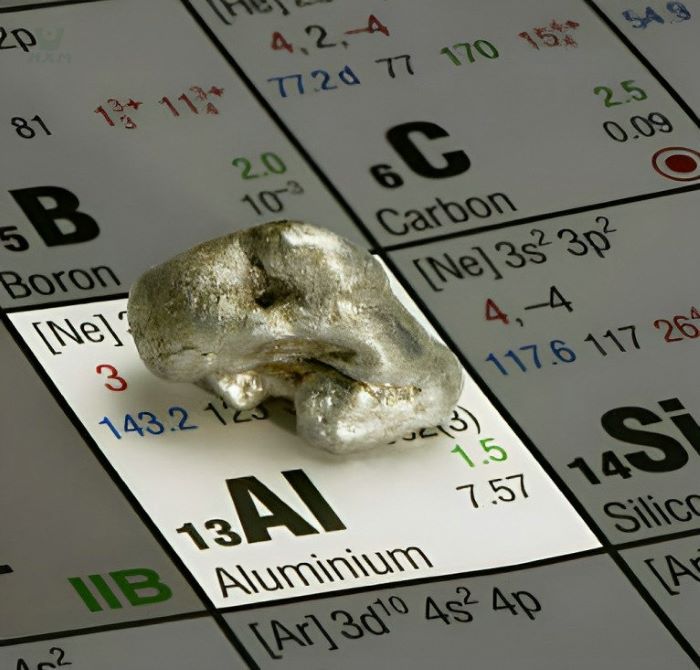

Aluminum is a chemical element with the symbol Al and atomic number 13. It is a silvery-white, lightweight metal that boasts several remarkable properties, making it a versatile material in various industrial applications. Here’s a more detailed exploration of aluminum:

Atomic Structure and Composition

Aluminum is an element, and its atoms consist of 13 electrons, 13 protons, and 14 neutrons in its most stable form. This atomic structure grants aluminum its specific chemical and physical properties.

The Properties and Characteristics of Aluminum

- Lightweight Nature: Aluminum is renowned for its low density, making it exceptionally lightweight. In fact, aluminum's density is approximately one-third that of steel. This quality makes it ideal for applications where weight reduction is crucial, such as in the aerospace industry, where it is a primary choice for aircraft construction.

- Corrosion Resistance: One of the most distinctive features of aluminum is its natural corrosion resistance. When exposed to the atmosphere, aluminum rapidly forms a thin layer of aluminum oxide on its surface. This oxide layer acts as a protective barrier, preventing further corrosion and ensuring the metal's durability even in challenging environments. The impermeable aluminum oxide layer is a significant reason for the metal's extensive use in outdoor and marine applications.

- High Thermal Conductivity: Aluminum exhibits excellent thermal conductivity. It can efficiently transfer and dissipate heat, making it an essential component in heat exchangers, radiators, and various cooling systems.

- Electrical Conductivity: In addition to thermal conductivity, aluminum also boasts high electrical conductivity. This characteristic is crucial in electrical wiring, where efficient electrical current transmission is essential.

- Malleability and Ductility: Aluminum is highly malleable and ductile, meaning it can be easily shaped and formed into various structures, making it suitable for intricate designs and complex components.

- Aluminum Alloys: Pure aluminum is rarely used in industrial applications. Instead, it is alloyed with other elements, such as copper, magnesium, or silicon, to enhance specific properties. Different alloys are created to meet the requirements of various industries. For instance, aluminum-silicon alloys are used in the automotive industry, whereas aluminum-magnesium alloys are employed in aircraft construction due to their exceptional strength-to-weight ratio.

Understanding these fundamental properties and characteristics of aluminum is essential for anyone involved in aluminum welding or working with this versatile metal. The choice of aluminum alloy and welding techniques is heavily influenced by these features.

The Different Alloys Used in Welding

Weld aluminium encompasses a variety of alloys, each tailored to suit specific applications and industries. Understanding these alloys is crucial for achieving successful welds. Here, we explore the science behind different aluminum alloys:

- 1XXX Series: This series primarily contains pure aluminum, with a minimum of 99% aluminum content. Due to its excellent corrosion resistance, these alloys find use in applications where high corrosion resistance is required. However, they are not known for their strength.

- 2XXX Series: Alloys in this series are primarily made of aluminum with copper as the main alloying element. They are recognized for their high strength and are often used in aerospace applications, including aircraft components.

- 3XXX Series: With manganese as the primary alloying element, these alloys are known for their moderate strength and excellent formability. They are widely used in applications such as cooking utensils, heat exchangers, and automotive components.

- 4XXX Series: These alloys primarily contain silicon, making them highly weldable. They are commonly used in welding and brazing applications, making them suitable for heat exchangers and automotive parts.

- 5XXX Series: Alloys in this series include magnesium as the primary alloying element. They are known for their high strength and corrosion resistance. These alloys are commonly used in marine applications and for manufacturing welded structures.

- 6XXX Series: These alloys contain magnesium and silicon as their primary alloying elements. They are valued for their combination of strength, formability, and corrosion resistance. They find extensive use in various structural and architectural applications.

- 7XXX Series: With zinc as the primary alloying element, these alloys are appreciated for their high strength. They are commonly used in aerospace and military applications, where robust materials are essential.

- 8XXX Series: This series includes alloys with various alloying elements. They are not as common as other series and are often used for specialized applications.

Understanding the specific alloy and its properties is vital for ensuring the success of an aluminum welding project. The choice of the right alloy will depend on the project’s requirements, whether it’s for its strength, formability, or corrosion resistance. Aluminum alloy manufacturers produce a wide range of alloys to meet the diverse needs of industries and applications.

-Alloyours aluminum alloy manufacturers

Preparing to Weld Aluminium

Weld aluminium requires meticulous preparation to ensure successful and strong welds. Here, we delve into the scientific aspects of the two key aspects of aluminum welding preparation:

Cleaning and Surface Preparation

Cleaning the aluminum surface is crucial for achieving high-quality welds. The process involves the removal of impurities and oxides from the surface. Here’s a breakdown of this essential step:

- Oxide Layer Removal: Aluminum forms a thin but tenacious oxide layer on its surface. This layer must be eliminated before welding. Typically, this is done by mechanical methods like wire brushing, grinding, or sanding.

- Chemical Cleaning: Acid or alkaline cleaning solutions can be used to further remove oxides and contaminants. Acidic cleaners are particularly effective in dissolving oxides, while alkaline cleaners help neutralize and clean the surface.

- Specialized Techniques: In some cases, especially for critical applications like aerospace, more advanced techniques such as alkaline cleaning followed by deoxidizing agents are employed to ensure a clean surface.

Safety Precautions and Equipment

Aluminum welding poses unique safety challenges due to the metal’s properties and the potential for producing harmful fumes. Proper safety measures are essential:

- Ventilation: Adequate ventilation is crucial to disperse potentially hazardous fumes. This is particularly important when using techniques like MIG and TIG welding.

- Personal Protective Equipment (PPE): Welders should wear appropriate PPE, including welding helmets with proper filters, welding gloves, and flame-resistant clothing. Respirators may be necessary depending on the welding method.

- Fire Prevention: Aluminum dust and spatter can be flammable. Welding areas must be free from flammable materials, and fire extinguishers should be readily available.

- Fume Extraction: In some cases, fume extraction systems can be employed to capture and remove welding fumes, providing a safer working environment.

Proper preparation, cleaning, and safety measures are vital for successful aluminum welding. By understanding the science behind these steps, welders and aluminum alloy manufacturers can achieve strong, reliable welds while ensuring their safety and the quality of the final product.

-Alloyours aluminum alloy manufacturers

Welding Methods for Aluminum

When it comes to weld aluminium, several methods can be employed, each with its unique advantages and challenges. Let’s delve into these methods and explore the science behind them:

| Welding Methods for Aluminum | Principle | Scientific Precision | Applications |

|---|---|---|---|

| TIG Welding (Tungsten Inert Gas) | Utilizes a non-consumable tungsten electrode that generates an electric arc and uses inert gas (typically argon) to shield the weld area. | Provides precise control over heat input, fine weld bead control, minimal heat-affected zone, reducing distortion and crack formation. | Aerospace components, critical structural elements, high-quality welds. |

| MIG Welding (Metal Inert Gas) | Employs a consumable wire electrode and inert gas (typically argon or a mixture of argon and helium) to shield the welding area. | Offers high productivity, efficiency, and excellent weld penetration. Continuous wire feed simplifies the process. | Automotive, construction, general fabrication, applications requiring speed and productivity. |

| Other Methods and Their Applications | – Oxy-Acetylene Welding: Uses oxygen and acetylene for high-temperature flame welding. – Resistance Spot Welding: Applies pressure and electrical current for specific point welds. – Friction Stir Welding: A solid-state process that creates defect-free joints without melting. | – Oxy-Acetylene: Suitable for repairs and in areas without electricity. – Spot Welding: Common in the automotive industry. – Friction Stir Welding: Strong, defect-free joints. | – Oxy-Acetylene: Repairs, remote locations. – Spot Welding: Automotive. – Friction Stir Welding: Various industrial applications. |

-Alloyours aluminum alloy manufacturers

Techniques to weld aluminium

Controlling Heat and Managing Conductivity

Weld aluminium requires precise control over heat, as aluminum has a relatively high thermal conductivity. If the heat input is too high, the aluminum can become overheated, leading to distortion, burn-through, and a weakened weld. Conversely, if the heat input is too low, it may not be sufficient to create a sound weld.

To control heat, welding operators must adjust the current, voltage, and travel speed carefully. TIG welding, for example, provides exceptional control over heat input due to its fine current adjustment and the ability to use a foot pedal for real-time adjustments. For MIG welding, voltage settings and wire feed speeds must be optimized to control heat.

Proper heat control also helps in preventing the formation of a large heat-affected zone (HAZ) around the weld, minimizing the risk of cracking or weakening the joint. This control over heat, combined with aluminum’s high thermal conductivity, makes aluminum welding a challenging but precise process.

Using Filler Material for a Strong Bond

Filler material plays a crucial role in weld aluminium. While aluminum has self-protecting oxide layers that must be removed during welding, a suitable filler material is needed to ensure a strong bond. Aluminum welding typically uses filler rods or wires of compatible alloys, such as 4043, 5356, or 4047.

The choice of filler material depends on the specific aluminum alloy being welded and the application. The filler material should have similar composition and properties to the base material, ensuring a coherent and reliable weld. When molten, the filler material fuses with the base metal, forming a homogeneous bond.

It’s essential to feed the filler material accurately and maintain a stable arc during the welding process. Precise filler deposition allows for uniform distribution along the weld, enhancing strength and integrity. The skilled manipulation of filler material ensures the formation of a robust and durable aluminum weld.

Overall, the combination of heat control and proper filler material usage is essential for achieving high-quality, precise aluminum welds with the desired mechanical properties. These techniques are fundamental for welders to master when working with aluminum.

Common Challenges and Troubleshooting

Dealing with Overheating and Warping

Overheating and warping are common challenges when weld aluminium due to its high thermal conductivity and low melting point. Overheating can lead to a weakened weld and warping, which affects the alignment and integrity of the welded parts.

To address overheating, it’s crucial to control the heat input effectively. This can be achieved by adjusting the welding parameters, such as current, voltage, and travel speed, to maintain a precise balance. Additionally, using a pulsing technique in TIG welding or a spool gun in MIG welding can help control heat by allowing the welder to alternate between high and low heat inputs.

To prevent warping, it’s essential to use fixturing and clamping techniques to maintain the alignment of the parts being welded. Fixtures can help distribute the heat evenly and minimize the deformation caused by temperature differentials. Proper preheating of thicker aluminum materials can also reduce the risk of warping by minimizing temperature gradients during welding.

Strategies for Fixing Cracks and Voids

Weld aluminium can sometimes lead to issues like cracks or voids in the weld. These defects can compromise the structural integrity of the weld and should be addressed effectively.

- Cracks: To address cracks, first, identify the root cause. Cracks can result from factors like inadequate preheating, excessive heat, or improper filler material. Repairing a crack involves grinding out the crack, re-preparing the surface, and rewelding the affected area using suitable filler material. Post-weld heat treatment may also be necessary to relieve residual stresses and prevent crack propagation.

- Voids: Voids or porosity in the weld can be caused by gas entrapment during welding. To repair voids, the affected area should be ground down to clean, solid metal, and then rewelded. Welders can reduce the likelihood of voids by ensuring proper gas shielding, using the appropriate welding technique, and avoiding contaminants on the base metal.

Regular inspection and quality control are essential in detecting these issues. By understanding the causes and implementing appropriate strategies for fixing cracks and voids, welders and aluminum alloy manufacturers can maintain the integrity of aluminum welds.

In addressing these challenges, welders and aluminum alloy manufacturers can ensure the reliability and quality of their aluminum welds, making them well-prepared to tackle the intricacies of weld aluminum effectively.

conclusion

In conclusion, mastering the art of aluminum welding is of paramount significance in various industries, from aerospace to automotive, where this lightweight yet robust metal is a staple. Achieving high-quality aluminum welds demands a deep understanding of its unique properties, alloys, and welding techniques.

By constantly exploring the complexities of aluminum welding and adapting to evolving technologies, welders can contribute to the development of safer and more efficient products. They also play a crucial role in ensuring the structural integrity and longevity of aluminum structures, which are prevalent in our modern world.

In this ever-evolving field, the encouragement for continuous learning and improvement is paramount. Staying updated on the latest advances in welding technologies, safety protocols, and material sciences is not only beneficial for welders but also vital for the industries that rely on their expertise. With dedication and a commitment to enhancing their skills, welders will continue to be at the forefront of aluminum welding, further advancing the capabilities of this remarkable material.

As aluminum continues to be an indispensable material in our technologically advanced world, those who master the art of welding it will be the torchbearers of innovation and excellence. It is through their expertise and unwavering dedication that aluminum’s potential will continue to be harnessed to its fullest extent.

By working in collaboration with aluminum alloy manufacturers, welders are pivotal in bringing innovation to various industries, thus ensuring that the limitless potential of aluminum is fully realized. This synthesis of expertise, knowledge, and continuous improvement promises a future where aluminum remains a cornerstone of progress and technological advancement.