Copper, with its distinctive reddish-brown hue and excellent electrical conductivity, has been utilized by civilizations for thousands of years. But have you ever wondered if copper is simply a pure elemental metal or if it falls into the category of alloys? In this intriguing exploration, we aim to unravel the question: Is copper an alloy?

is copper an alloy?

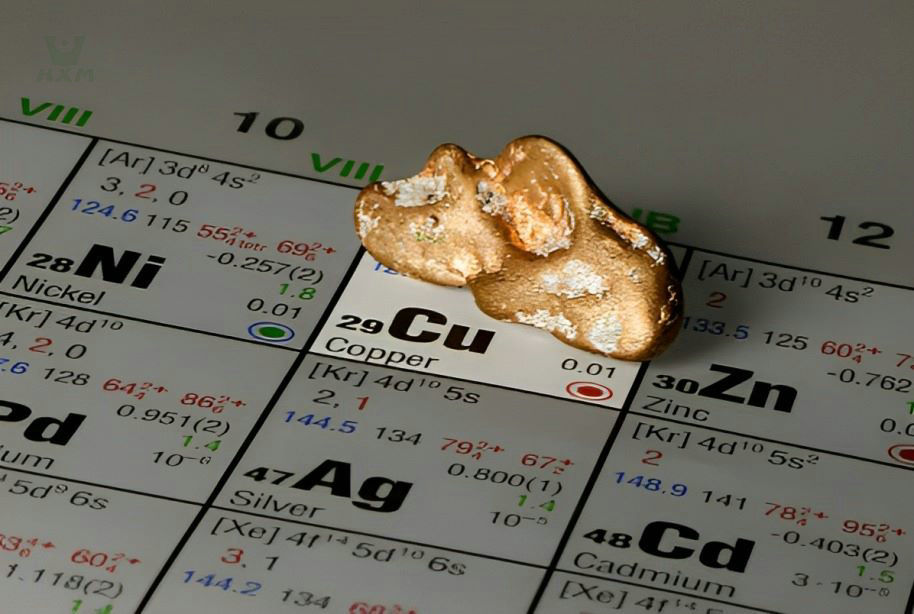

Copper, in its pure form, is not an alloy but an elemental metal. It is represented by the chemical symbol Cu on the periodic table. However, copper is frequently combined with other elements to create alloys that possess specific properties suited for various applications. Copper alloys are mixtures of copper with one or more additional elements, typically metals like zinc, tin, or nickel. These alloys offer enhanced characteristics such as improved strength, durability, corrosion resistance, or color variation. Common copper alloys include bronze, brass, and cupronickel.

To truly comprehend the nature of copper, we must delve into the fascinating realm of alloys. An alloy is a mixture of two or more elements, where at least one element is a metal. While copper can exist as a pure metal, it is frequently combined with other elements to form alloys that possess specific properties tailored to various applications.

Copper as an Elemental Metal

Copper is a chemical element with the symbol Cu and atomic number 29. It is a soft, malleable, and ductile metal with a reddish-orange color. It belongs to the group of transition metals and is found naturally in various minerals and ores.

Characteristics of Copper

Copper possesses several characteristic properties that contribute to its wide range of applications:

Excellent Conductivity

Copper is known for its exceptional thermal and electrical conductivity. It efficiently transfers heat and allows the flow of electricity, making it ideal for electrical wiring, power transmission, and heat exchange systems.

Malleability and Ductility

Copper is highly malleable and ductile, meaning it can be easily hammered, shaped, and stretched into various forms without breaking. This property enables the production of intricate copper components and facilitates its use in plumbing systems, architectural applications, and artistic creations.

Corrosion Resistance

Copper exhibits excellent corrosion resistance, making it highly durable and long-lasting. It forms a protective layer, called a patina, over time, which helps prevent further corrosion and retains its attractive appearance.

Antibacterial Properties

Copper possesses natural antimicrobial properties, inhibiting the growth of bacteria, viruses, and fungi. This characteristic has led to its use in healthcare facilities, food processing, and touch surfaces where hygiene is essential.

Appealing Appearance

Copper has a distinctive reddish-orange color that is aesthetically pleasing. Its warm tone adds a touch of elegance to architectural designs, decorative elements, and artistic creations.

Recyclability

Copper is highly recyclable, meaning it can be reused and reprocessed without losing its properties. Recycling copper reduces the need for extracting new resources and contributes to sustainable practices.

Copper's role as a pure metal in various industries

Copper, as a pure metal, plays a vital role in numerous industries due to its exceptional properties and versatility. Let’s explore its significance across different sectors and its importance for copper suppliers.

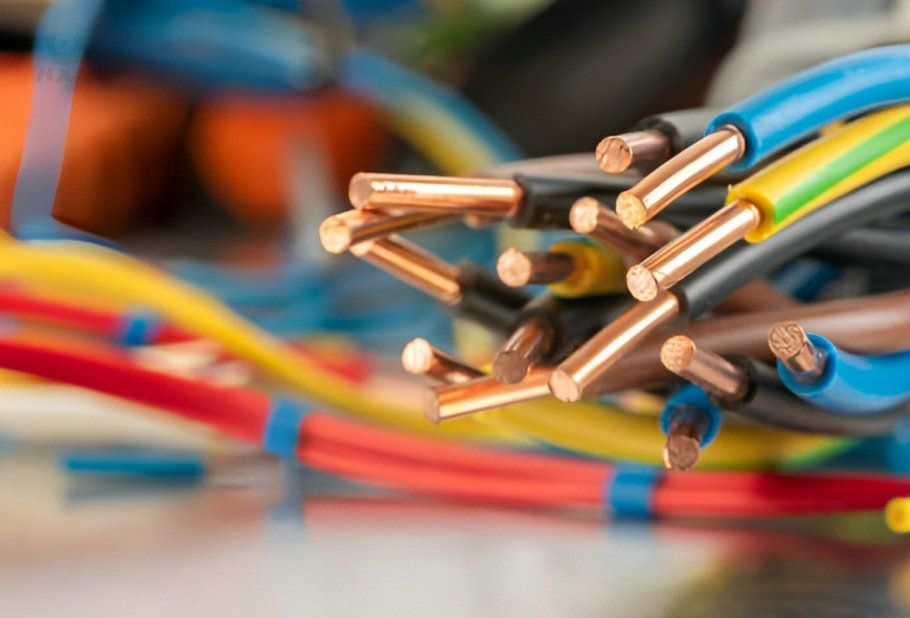

Electrical and Electronics Industry

Copper's high electrical conductivity makes it the preferred choice for electrical wiring, cables, and busbars. It is widely used in power transmission and distribution systems, as well as in electric motors, transformers, and generators. The electronics industry relies on copper for printed circuit boards (PCBs), connectors, and integrated circuits due to its excellent conductivity and reliability.

Construction and Architecture

Copper is extensively used in the construction industry for plumbing systems, roofing, and guttering due to its corrosion resistance and durability. Its attractive appearance makes it an appealing choice for architectural applications, including facades, decorative elements, and interior design.

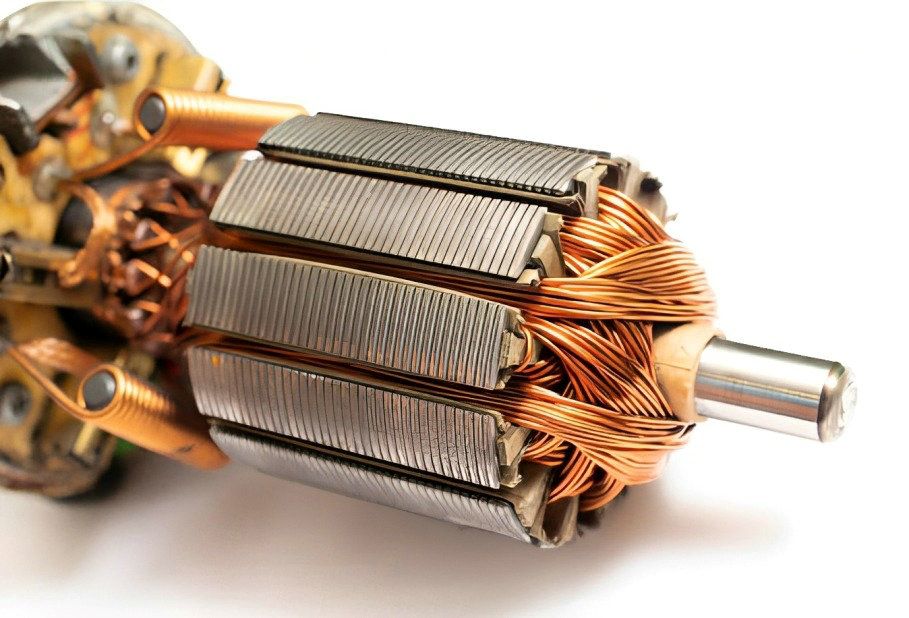

Industrial Machinery and Equipment

Copper's heat conductivity and corrosion resistance make it suitable for heat exchangers, air conditioning systems, and refrigeration units. It is utilized in the manufacturing of industrial machinery, such as pumps, valves, and bearings, due to its high strength and resistance to wear.

Automotive and Transportation

Copper plays a crucial role in automotive applications, including wiring harnesses, connectors, and electric vehicle components. It is used in radiator cores, brake systems, and various engine components due to its excellent heat transfer properties and resistance to vibration and corrosion.

Coinage and Artistic Applications

Copper is historically renowned for its use in coinage, due to its durability, malleability, and resistance to corrosion. Artists and craftsmen utilize copper for sculptures, artwork, and jewelry, taking advantage of its unique reddish color and workability.

Copper suppliers play a crucial role in meeting the diverse needs of these industries, providing high-quality copper materials for manufacturing, construction, and artistic endeavors. The availability of pure copper ensures the reliability and performance of products across multiple sectors, contributing to technological advancements and aesthetic creations alike.

Copper Alloys

An alloy is a material composed of two or more elements, where at least one element is a metal. These elements are combined through mixing or melting, resulting in a solid solution with distinct properties different from those of the individual elements. The characteristics of alloys depend on factors such as the composition, ratio of elements, and the microstructure formed during the alloying process.

Alloys often exhibit improved properties compared to their constituent elements. These properties can include enhanced strength, hardness, corrosion resistance, heat resistance, electrical conductivity, and more. Copper suppliers by carefully selecting and combining elements, alloys can be tailored to meet specific requirements for various applications.

Characteristics of Alloys

Alloys possess several characteristic properties that differentiate them from pure metals and other materials:

Improved Strength

Alloys often exhibit higher strength compared to their constituent elements. The presence of multiple elements allows for a more efficient arrangement of atoms, leading to stronger metallic bonds and increased resistance to deformation or breakage.

Enhanced Hardness

Alloys can be engineered to have greater hardness than pure metals. This is achieved by introducing elements that form intermetallic compounds or solid solution strengthening, resulting in a harder material suitable for wear-resistant applications.

Superior Corrosion Resistance

Certain alloy compositions can provide enhanced corrosion resistance compared to pure metals. The addition of corrosion-resistant elements forms a protective barrier or alters the material’s microstructure, inhibiting the degradation caused by exposure to corrosive environments.

Tailored Thermal and Electrical Conductivity

Alloys offer the ability to modify thermal and electrical conductivity by adjusting the composition and structure. This versatility allows for the creation of materials with specific conductivity properties to meet the requirements of different applications.

Increased Melting Point

Alloys often have higher melting points than pure metals due to the influence of different elements. This characteristic is crucial in applications where high temperatures are encountered, such as aerospace, industrial furnaces, and engine components.

Altered Physical Appearance

Alloys can exhibit unique colors, textures, and surface finishes that differentiate them from pure metals. This property is utilized in decorative applications, jewelry, and artistic creations.

Copper suppliers play a crucial role in providing a diverse range of copper alloys to meet the specific needs of industries and applications. These copper suppliers ensure the availability of high-quality copper materials, offering various compositions, forms, and sizes. With their expertise and knowledge, copper suppliers enable manufacturers, builders, artisans, and other professionals to access the necessary copper alloys for their projects. Whether it’s bronze for sculptures, brass for plumbing fixtures, or specialized copper alloys for electrical components, the expertise and reliable supply chain provided by copper suppliers are essential for the successful implementation of copper-based solutions.

Different types of copper alloys

Copper alloys encompass a wide range of compositions, each with unique properties and applications. Let’s explore some of the most common types of copper alloys and their compositions:

Bronze

Composition: Bronze is primarily composed of copper (Cu) combined with tin (Sn), although other elements such as aluminum (Al), silicon (Si), and phosphorus (P) may also be present.

Properties and Applications: Bronze alloys offer excellent strength, durability, and corrosion resistance. They are commonly used in statues, musical instruments, bearings, and historical artifacts.

Brass

Composition: Brass consists mainly of copper (Cu) combined with zinc (Zn), with varying ratios depending on the desired properties. Additional elements such as lead (Pb) or tin (Sn) can also be added.

Properties and Applications: Brass alloys exhibit good malleability, corrosion resistance, and have a golden appearance. They find extensive use in plumbing fixtures, electrical connectors, decorative items, musical instruments, and more.

Cupronickel

Composition: Cupronickel alloys combine copper (Cu) with nickel (Ni) in various proportions. The most common composition is around 75% copper and 25% nickel.

Properties and Applications: Cupronickel alloys offer excellent resistance to corrosion, especially in marine environments. They are widely used in shipbuilding, marine equipment, coinage, and heat exchangers.

Copper-nickel-zinc alloys (Nickel Silvers)

Composition: These alloys, also known as nickel silvers, contain copper (Cu) as the base metal, with nickel (Ni) and zinc (Zn) as the primary alloying elements. Additional elements such as manganese (Mn) or iron (Fe) can be included.

Properties and Applications: Copper-nickel-zinc alloys exhibit good strength, ductility, and are often used in jewelry, silverware, musical instruments, and decorative applications.

Copper-based alloys with additional elements

Composition: Copper alloys can be further customized by adding elements such as aluminum (Al), silicon (Si), manganese (Mn), or others to enhance specific properties.

Properties and Applications: These alloys offer a wide range of characteristics, including high strength, thermal stability, improved electrical conductivity, or resistance to corrosion, and find applications in various industrial sectors.

These are just a few examples of the many types of copper alloys available. Copper suppliers offer a diverse selection of compositions to meet the specific requirements of different industries, ensuring the availability of materials with tailored properties and applications.

Tracing the Historical Use of Copper Alloys in Ancient Civilizations

Copper alloys have a rich history dating back to ancient civilizations, and their significance is closely tied to the contributions of copper suppliers throughout the ages.

Bronze Age Revolution

The discovery and mastery of copper alloys, particularly bronze (copper combined with tin), marked a revolutionary period known as the Bronze Age.

Ancient civilizations such as the Egyptians, Greeks, Mesopotamians, and Indus Valley inhabitants embraced the strength and versatility of bronze for tools, weapons, and decorative items.

Copper suppliers played a pivotal role in providing the necessary copper and tin materials for the production of bronze, enabling the flourishing of ancient civilizations.

Cultural and Artistic Flourishing

Copper alloys, particularly bronze, played a significant role in the cultural and artistic expressions of ancient civilizations.

Bronze sculptures, statues, and ceremonial objects reflected the artistic skills and cultural beliefs of societies such as the Greeks, Romans, and Chinese.

Copper suppliers facilitated the availability of copper alloys, supporting the artistic endeavors of sculptors, artisans, and craftsmen in creating enduring masterpieces.

Trade and Exchange

The demand for copper alloys led to extensive trade networks, facilitating the exchange of raw materials and finished products across vast regions.

Copper suppliers acted as key players in this trade network, ensuring the availability and distribution of copper and other alloying elements to meet the needs of diverse civilizations.

Technological Advancements

The use of copper alloys in ancient civilizations marked significant technological advancements.

Bronze tools and weapons were superior to their stone counterparts, allowing for more efficient agriculture, construction, and warfare.

Tracing the historical use of copper alloys reveals their profound impact on ancient civilizations. The availability and expertise of copper suppliers were instrumental in enabling the development of bronze technologies, fostering cultural and artistic expressions, and contributing to technological advancements that shaped the course of human history. Today, the legacy of copper alloys continues to inspire and drive innovation across industries, with copper suppliers continuing to play a crucial role in meeting the demands of modern applications.

conclusion

Throughout this exploration of copper alloys, we have delved into various aspects that highlight the significance and versatility of these materials. We traced the historical use of copper alloys in ancient civilizations, recognizing the role played by copper suppliers in facilitating their availability. We also examined the cultural and artistic impact of copper alloys, as well as their contributions to technological advancements across industries.

While copper itself is an elemental metal, it can be alloyed with other elements to form a wide range of copper alloys with distinct properties and applications. The use of copper alloys has been prevalent throughout history and continues to be vital in numerous industries today. Copper alloys offer enhanced strength, improved corrosion resistance, and tailored characteristics that make them invaluable for various applications.

Copper alloys play an integral role in diverse industries, including construction, electronics, automotive, art, and more. The availability of different types of copper alloys enables engineers, designers, and manufacturers to tailor materials to meet specific requirements. Copper suppliers play a crucial role in providing high-quality copper alloys, supporting innovation, and driving progress across industries.