Copper, an essential metal in our daily lives, has been cherished for centuries due to its remarkable properties and versatile applications. From electrical wiring to decorative elements, copper’s unique attributes have made it a cornerstone of modern civilization. Yet, amidst its many fascinating characteristics, there is a lingering question that often sparks curiosity: Is copper magnetic?

is copper magnetic?

No, copper is not magnetic. It lacks the magnetic properties of materials like iron and nickel. This non-magnetic nature is a unique aspect of copper that often surprises many. While copper is an excellent conductor of electricity and heat, its electrons’ arrangement does not produce a magnetic field, making it impervious to magnetism. This characteristic is essential in various applications, especially in electrical wiring and devices, as it prevents interference with magnetic fields and ensures stable performance. So, rest assured, when you encounter copper in daily life, it won’t be pulled towards magnets, but it will continue to be an indispensable and reliable material in countless industries.

In this blog, we will delve into the intriguing world of copper’s magnetism and explore the science behind this phenomenon. We will unravel the mystery of copper’s non-magnetic nature and shed light on the factors that contribute to this intriguing property. So, if you’ve ever wondered why copper doesn’t adhere to magnets like its ferrous counterparts, join us on this fascinating journey of discovery.

The Science Behind Magnetism

Magnetism is a captivating natural phenomenon that has intrigued scientists and curious minds for centuries. At its core, magnetism involves the interactions between charged particles and their intrinsic magnetic fields. Understanding the science behind magnetism unravels the secrets of how certain materials become magnetic and respond to magnetic fields.

magnetic materials

Magnetic materials are substances that exhibit a response to magnetic fields, displaying magnetic properties. There are three main types of magnetic materials: ferromagnetic, paramagnetic, and diamagnetic.

Ferromagnetic materials are characterized by their strong magnetic properties and the ability to become permanently magnetized. They consist of small magnetic domains, each with aligned magnetic moments, which creates a macroscopic magnetic field. Ferromagnetic materials retain their magnetization even after the external magnetic field is removed. Common examples of ferromagnetic materials include iron, nickel, cobalt, and their alloys. These materials are widely used in applications like magnetic storage media, transformers, and electric motors.

Paramagnetic materials exhibit weak attraction to external magnetic fields. When exposed to a magnetic field, their atomic or molecular magnetic moments align with the field, but the alignment is temporary and disappears when the field is removed. Paramagnetic materials include substances like aluminum, platinum, and oxygen. While their magnetic effects are relatively weak, they are essential in magnetic resonance imaging (MRI) and certain scientific experiments.

Diamagnetic materials are weakly repelled by magnetic fields. When exposed to a magnetic field, their atomic currents generate a magnetic moment in the opposite direction to the applied field. Common examples of diamagnetic materials are copper, silver, and water. Although their magnetic properties are feeble, they are crucial in levitation experiments and magnetic shielding applications.

Understanding the distinct behavior of these magnetic materials is essential in various fields of science and engineering, enabling the development of innovative technologies and applications that harness the power of magnetism.

Electron configuration and its role in magnetism

Electron configuration plays a fundamental role in determining the magnetic properties of materials. Magnetism arises from the motion of charged particles, particularly electrons, within atoms.

In an atom, electrons occupy specific energy levels or orbitals around the nucleus. Each electron has a magnetic moment associated with its spin and orbital angular momentum. The way these electrons are arranged and their spin alignment within an atom’s electron orbitals contribute to the overall magnetic behavior of the material.

Ferromagnetic materials, like iron and nickel, have unpaired electrons in their electron configuration. These unpaired electrons align their spins parallel to each other, creating a net magnetic moment within each atom. When subjected to an external magnetic field, these magnetic moments align in the same direction, leading to macroscopic magnetization.

Paramagnetic materials have partially filled electron shells with unpaired electrons. In the presence of an external magnetic field, the electron spins partially align with the field, resulting in weak magnetism.

Diamagnetic materials, on the other hand, have all their electron shells fully paired, resulting in zero net magnetic moment. They exhibit weak repulsion when subjected to an external magnetic field.

By understanding electron configuration and its influence on magnetism, scientists and engineers can predict and manipulate the magnetic properties of materials, enabling the design of magnetic devices, storage media, and various technological applications.

Copper's Non-Magnetic Nature

Copper, an essential metal known for its versatility and conductivity, possesses a unique property that sets it apart from other metals—its non-magnetic nature. Unlike some of its magnetic counterparts, copper does not exhibit any significant magnetic properties, making it an intriguing subject of study and application in various industries.

copper's atomic structure

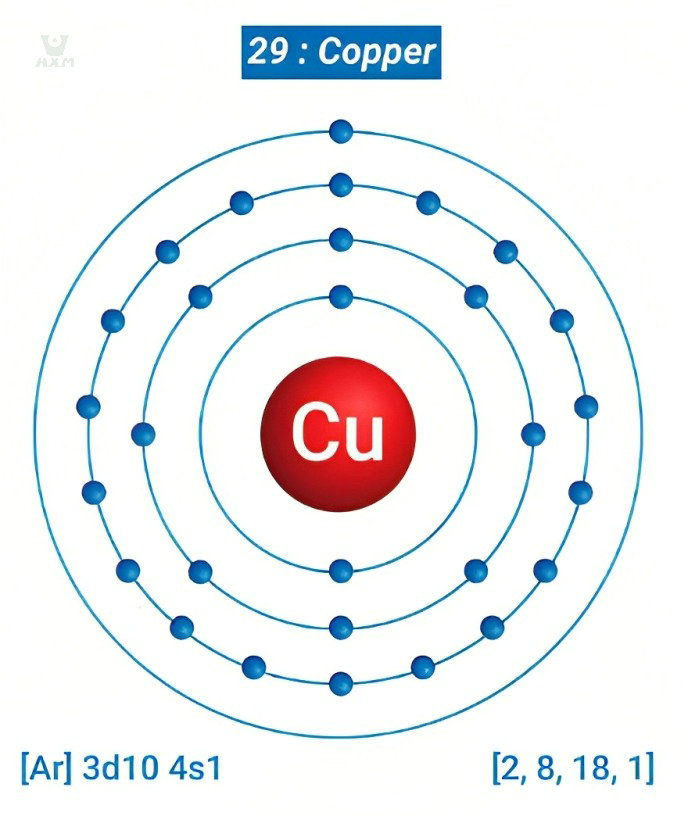

Copper, with the chemical symbol Cu and atomic number 29, possesses a well-defined atomic structure that plays a crucial role in its non-magnetic nature. At its core, a copper atom consists of a dense nucleus, composed of protons and neutrons, surrounded by a cloud of electrons.

The electron arrangement in copper follows a specific pattern based on the filling of energy levels or electron shells. Copper has a total of 29 electrons distributed in different electron orbitals. The first and innermost shell can hold up to 2 electrons, the second shell can accommodate up to 8 electrons, and the third shell, which is partially filled, can hold up to 18 electrons.

-Alloyours copper manufactures

In copper’s case, the electron configuration is [Ar] 3d^10 4s^1, where [Ar] represents the electron configuration of the noble gas argon (1s^2 2s^2 2p^6 3s^2 3p^6). The outermost electron in copper occupies the 4s orbital, and the 3d orbitals are filled with 10 electrons.

The unique electron arrangement of copper contributes to its non-magnetic nature. Unlike ferromagnetic materials with unpaired electrons, copper’s electron configuration lacks unpaired spins. As a result, the magnetic moments of the individual electrons cancel each other out, leaving copper with negligible net magnetic properties.

This property is of great significance in numerous applications, especially in electrical and electronic industries. Copper’s non-magnetic nature ensures minimal interference in magnetic fields, making it an ideal choice for manufacturing various electrical components, wires, and conductors. Its exceptional electrical conductivity and non-magnetic behavior make copper a crucial material in modern technology and industrial applications. Copper manufacturers appreciate these properties, as they enable the production of high-quality materials essential for our daily lives.

Comparison with magnetic materials

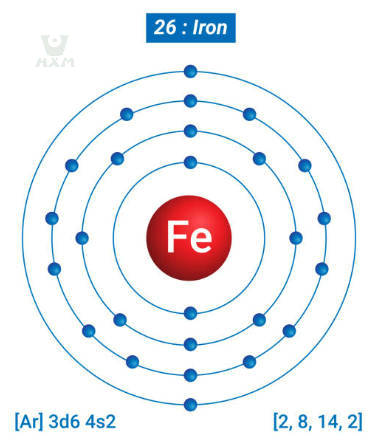

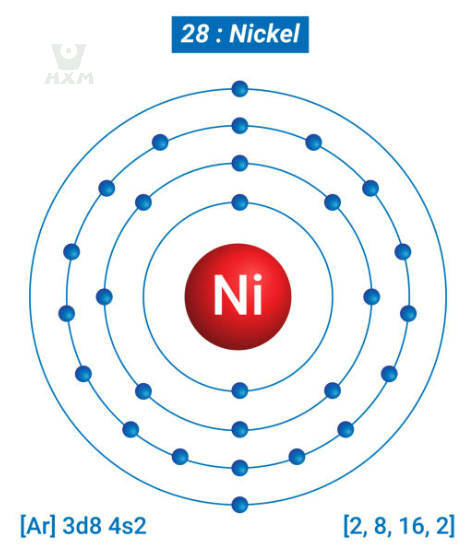

When comparing copper with magnetic materials like iron and nickel, one of the most significant distinctions lies in their electron configurations and resulting magnetic properties. As mentioned earlier, copper’s electron arrangement lacks unpaired spins, rendering it non-magnetic. On the contrary, iron and nickel, two ferromagnetic metals, possess electron configurations that accommodate unpaired electrons in their outermost shells.

-Alloyours copper manufactures

-Alloyours copper manufactures

In iron, the electron configuration is [Ar] 3d^6 4s^2, and in nickel, it is [Ar] 3d^8 4s^2. Both elements have unpaired electrons in their 3d orbitals, enabling the alignment of magnetic moments within their atoms. When placed in an external magnetic field, iron and nickel exhibit strong magnetization due to the parallel alignment of these magnetic moments.

Copper’s non-magnetic nature, along with its excellent electrical conductivity and thermal properties, makes it a sought-after material in various industries. For copper manufacturers, this unique property is particularly advantageous in applications where magnetic interference must be minimized, such as in electrical wiring, circuits, and sensitive electronic devices. Additionally, copper’s non-magnetic behavior makes it suitable for use in medical equipment and magnetic resonance imaging (MRI) systems, where magnetic materials would distort imaging results. Overall, the comparison highlights the value of copper’s non-magnetic property and its significance in diverse industrial and technological applications.

How to prove that copper is not magnetic?

Copper’s non-magnetic nature can be easily demonstrated by conducting a simple experiment using a magnetic field. To showcase copper’s lack of response to magnetic fields, you will need a small piece of pure copper, a strong magnet, and a flat surface.

- Step 1: Place the copper piece on the flat surface.

- Step 2: Take the strong magnet and bring it close to the copper piece without touching it. Observe that the copper piece remains unaffected and does not attract or repel the magnet.

- Step 3: Now, perform the same experiment with a magnetic material like iron or nickel. Bring the magnet close to the iron or nickel piece, and you will notice that they respond to the magnetic field, either attracting or repelling the magnet.

This simple demonstration clearly illustrates that copper does not interact with magnetic fields. Its non-magnetic behavior is a result of its electron configuration, which lacks unpaired electrons to create a net magnetic moment.

Applications of Non-Magnetic Copper

The applications of non-magnetic copper are diverse and far-reaching, owing to its unique properties and wide array of industrial advantages. As a pivotal material in modern engineering and technology, non-magnetic copper finds itself at the core of numerous critical applications where magnetic interference must be minimized or eliminated. From electronics and telecommunications to aerospace and medical equipment, non-magnetic copper’s exceptional attributes have revolutionized various industries. Let’s explore the wide-ranging applications and the significant role that copper manufacturers play in meeting the demands of these specialized sectors.

Non-Magnetic Copper in Electrical&Electronic Devices

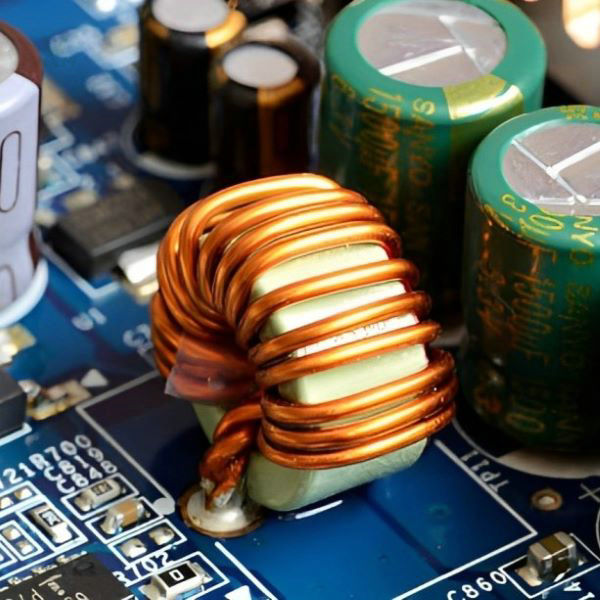

Non-magnetic copper plays a crucial role in the manufacturing of electrical and electronic devices. Its exceptional electrical conductivity and non-magnetic properties make it an ideal choice for wiring, connectors, and printed circuit boards. Copper’s ability to carry electrical currents without generating magnetic fields is of utmost importance in sensitive electronic components, ensuring minimal interference and accurate signal transmission. Copper manufacturers recognize its significance in enhancing the performance and reliability of various electronic devices, from smartphones to computers and advanced medical equipment.

-Alloyours copper manufactures

-Alloyours copper manufactures

Advantages in Specific Industries with Non-Magnetic Nature

In industries where magnetic interference can lead to operational issues, non-magnetic copper emerges as a preferred material choice. For instance, in aerospace and defense applications, non-magnetic copper alloys are used for sensitive equipment and radar systems, preventing disruptions caused by external magnetic fields. Similarly, in marine and underwater technologies, non-magnetic copper is invaluable for sonar systems and underwater cables, ensuring accurate readings and uninterrupted communication. Copper manufacturers cater to these industries’ needs by supplying non-magnetic copper alloys tailored to withstand demanding environments.

-Alloyours copper manufactures

-Alloyours copper manufactures

How Non-Magnetic Copper Contributes to Reducing Electromagnetic Interference

Electromagnetic interference (EMI) can adversely affect electronic devices’ performance, leading to data corruption or system malfunctions. Non-magnetic copper’s role in reducing EMI is indispensable. Its inherent non-magnetic properties shield sensitive components from external magnetic fields, providing a protective barrier against unwanted interference. This is particularly critical in medical settings, where non-magnetic copper is utilized in MRI machines, preventing magnetic distortion during imaging procedures. Copper manufacturers continuously innovate and produce advanced non-magnetic copper materials, ensuring that various industries benefit from its EMI-reduction capabilities, facilitating seamless operations and accurate data transmission.

Practical Implications

In the realm of materials science and engineering, understanding the practical implications of various properties is crucial for making informed decisions and achieving optimal outcomes. When it comes to copper and its diverse applications, grasping the practical implications of its unique characteristics opens up a world of possibilities in different industries. From electrical engineering to construction, copper’s exceptional attributes have a profound impact on material choices, design considerations, and the overall performance of countless products and systems. Let’s delve into the practical implications of copper’s properties and explore how they shape our modern world.

How Knowledge of Copper's Non-Magnetic Property Affects Material Choices

Understanding copper’s non-magnetic nature significantly influences material choices in various industries. Design engineers and manufacturers opt for non-magnetic copper alloys when crafting sensitive electronic devices, MRI machines, or aerospace components, where magnetic interference could compromise performance. The knowledge of this property allows them to select the right materials for specific applications, ensuring optimal functionality and reliability. Copper manufacturers play a pivotal role in providing tailored non-magnetic copper alloys to meet the precise needs of these industries, enabling seamless integration of copper’s unique advantages.

Real-World Applications and Industries that Benefit from Non-Magnetic Copper

The real-world applications of non-magnetic copper are diverse and essential. In electronics, non-magnetic copper is a staple for printed circuit boards, connectors, and high-speed data transmission lines, ensuring accurate signal propagation without magnetic interference. In aerospace, the use of non-magnetic copper alloys in navigation systems and communication devices enhances safety and efficiency during flight. Moreover, medical equipment, particularly MRI machines, relies on non-magnetic copper for distortion-free imaging. Copper manufacturers continually cater to these industries, supplying advanced non-magnetic copper materials that drive innovation and progress.

Advantages of Using Non-Magnetic Copper in Specific Scenarios

The advantages of employing non-magnetic copper extend beyond its EMI-reduction capabilities. Its high thermal conductivity makes it ideal for heat exchangers and cooling systems, enhancing overall efficiency and heat dissipation. Non-magnetic copper’s exceptional ductility and formability facilitate intricate shaping for complex components, allowing for customized designs in various applications. Additionally, its corrosion resistance ensures longevity, making it suitable for marine and chemical environments. The use of non-magnetic copper delivers enhanced performance, longevity, and reliability, making it a top choice in critical scenarios. Copper manufacturers continue to innovate, providing cutting-edge solutions for industries that prioritize precision and magnetic interference mitigation.

conclusion

In conclusion, the non-magnetic nature of copper stands as a remarkable attribute that has far-reaching implications across various industries. Through this exploration, we have come to recognize the importance of understanding copper’s unique properties and its impact on material choices and design considerations. From electronics to medical equipment and aerospace applications, copper’s non-magnetic feature plays a pivotal role in ensuring seamless operations and precision.

As copper manufacturers continue to innovate and provide cutting-edge solutions, it becomes evident that informed decision-making in material selection is key to achieving optimal performance and reliability. Embracing the versatility of copper and harnessing its exceptional attributes lead to advancements that drive progress in modern engineering and technology.

With a firm grasp on the practical implications of copper’s non-magnetic nature, we pave the way for groundbreaking innovations, fueling advancements in diverse industries. As we move forward, let us value the significance of this remarkable metal and leverage its potential to create a world of possibilities in our ever-evolving technological landscape.